|

Page number |

Image No. |

Transcription

|

Thumbnail |

| 1 |

2 |

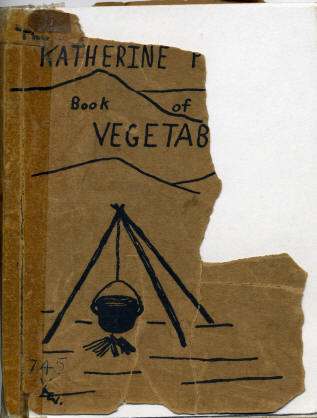

[2] Cover |

|

| 2 |

3 |

[Title page]

The Katherine Pettit Book of Vegetable Dyes

by

Wilmer Stone Viner

and

H.E. Scrope Viner

Cover Design by A.E. Viner

Saluda, N.C. The Excelsior Printers

1946 |

|

| 3 |

4 |

Copyright 1946 by

Mrs. Wilmer Stone Viner

Printed in the United States of America |

|

| |

5 |

[Photograph of Katherine Pettit] |

|

| |

6 |

DEDICATION

In affection and gratitude this book of vegetable dyes is

dedicated to the memory of

Katherine Pettit

whose memorial tablet in the Pine Mountain School Chapel reads as

follows:

"Katherine Pettit, 1869-1936, pioneer and trail-breaker. Forty

years she spent creating opportunity for mountain children here and

elsewhere. In life, she ever refused praise. In death, she is too

great for it." |

|

| |

7 |

Table of Contents

Frontispiece

Katherine Pettit Dedication

Introduction _________________________ Page 11

General Remarks__________________________15

Washing and Mordanting the Wool ._ __________18

Dyeing _________________________________ 23

Red _______________________ 24

Yellow _____________________ 32

Blue _______________________ 46

Green ______________________ 57

Brown ______________________59

Black ______________________ 61

|

|

| |

8 |

The Katherine Pettit Book

of Vegetable Dyes

INTRODUCTION

In almost all American families we find treasures of the past

that are carefully handed down from generation to generation, and

the one that is greatly treasured perhaps above all is the handwoven

coverlet with its lovely delicate colors mellowed by time. What a

history there is in these colors! In those bygone days you could not

go into the store and from a color card pick out just the dye you

wanted. The weaving by hand and coloring of these old coverlets was

no small task. And perhaps because it was such a slow, tedious task

is the reason why these treasures are so lasting and so dear to our

hearts.

There seems to be an awakening of renewed interest in natural

dyes throughout our country. Certainly there are no more beautiful

colors than can be gotten from our native trees, shrubs, and

flowers, and from the vegetable dyes that we import from other

countries. These treasured bits of weaving of the past, the colors

still bright, satisfying our eye with a peculiar beauty, surely are

the best proof of the lasting qualities of those dyes.

Nowadays interest has turned again to |

|

| |

9 |

handmade things: you see more

handlooms in homes; and delight is taken in reproducing the

intricate patterns of the old coverlets. It seems fitting that the

wools which go into the making of these things should be dyed

according to receipts known to our grandmothers, usually handed down

by word of mouth.

Dyeing with vegetable dyes is an art for the individual

craftsman, for these dyes cannot be produced wholesale. In modern

dyeworks the wools are dyed in enormous quantities, and this

wholesale method is destructive to art and the personality of the

dyes themselves. So here is an opportunity for the amateur weaver to

get his own colors. He can with his own hands gather the roots and

bark and flowers, make up the dye himself, and then watch the color

grow in the wools.

And what a wealth of material lies ready for the gathering in our

woodlands and on our hillsides! Such are Sumac berries, Sedge grass,

Poke berries, the little wild Coreopsis that grows on our mountain

sides, Pine needles, sweet Laurel leaves, Walnut hulls, to mention

only a few. Formerly many additional sources of dye were expressly

cultivated - Madder in our flower gardens, and Indigo

in the Southen States. Now Madder must

12 |

|

| |

10 |

be imported from Europe and

Indigo from China or India, while tropical dyewoods like Fustic and

Logwood can, of course, only be obtained through importing houses.

When thinking over old receipts which have been used and passed

on from one generation to the next, it is interesting to note how

the chemist's science again and again confirms the use of one or

other ingredient for the use of which the old dyer can give no

reason beyond the fact of its accepted necessity.

For example, the old receipts for setting up the Blue Pot call

for home-made "Lye". Chemistry shows the active ingredient of this

extract to be Potash in a form most effective for the reduction of

Indigo. So, from his practical experience, the early dyer was led to

employ an essential chemical, obtainable in every household by

homely methods. In each colonial home the ash-hopper was a familiar

object, holding in store a crude ingredient of the soap kettle and

the dyepot.

Again, the formulas for the preparation of lichens for the dyepot

all spoke of the use of stale urine as a fundamental; and we now

know that its constituent, ammonia, is needed to free the active

principal, Orcin, and change it into Orcein, the essential coloring

agent. For us, probably, the use of the chemical is

13 |

|

| |

11 |

the easier method, but

undoubtedly the homely formula was the more practical for the people

among whom it originated.

Likewise in the old homely sayings, we find hidden scientific

truths:- "A bright pot for a bright dye and a dark pot for a dark

dye," this is literally true since in many vegetable dyes there is

tannic acid, which, combining with the inside of a black pot sets

free an oxide of iron which will sadden bright colors.

The old colonial method of getting variegated effects on warp and

filling was by tieing wrappings of corn shucks around the material

at intervals, protecting the chain in this manner by a waterproof

covering from the action of the dye when the material was placed in

the dyepot. The tied and dyed work of today is an echo of this.

|

|

| |

12 |

In the following pages will be

found receipts for preparing and using dyes from many natural

sources, including those just mentioned; however, there are a few

general hints which may help the dyer to obtain best results. If at

all possible, dye out of doors, as sunshine and air are most helpful

in obtaining bright colors. A Tripod can be erected of poles at very

little expense and the dyepot hung from this by means of a chain and

hook. Two pots should be kept for use, an iron one for dark and a

brass pot for bright colors. "Don't crowd the pot," is an old

saying, meaning you should allow plenty of water in all processes,

so that the wool may be easily moved about. Stir the pot often, so

that the dye may "take" evenly, and for the same reason, tie the

wool in loose hanks, not tightly, or there will be light places in

it, where the dye has not penetrated properly. Wool that has been

mordanted and then has dried should be again damped before putting

into the dyebath, to insure its taking up the dye evenly.

In using dye woods, berries, flowers, roots, etc., the materials

can be tied loosely in cheese-cloth bags, to save the trouble later

on of picking the bits out of the dyed wool; however, my experience

is that the color comes

15 |

|

| |

13 |

out more readily if the

material is not so confined. Barks, roots, and hulls can be put into

the dyepot first, and the dye extracted by boiling1 before the

wool is put in; but when berries or flowers are the source of the

dye, they had best be put into the pot at the same time as the

mordanted wool, since prolonged boiling dulls the colors obtained

from these sources. This especially applies to ' 'dye-flower", also

to Madder, I find.

The time of year has a great effect on the results gotten when

using vegetable dyes. In the Springtime all dyes from bark ar6 weak,

because at that time the sap, rising in the tree, dilutes the

staining material in the bark which is the source of our dye. Again,

as flowers and berries g-et mature they yield a duller dye. On the

other hand, Sedge-grass gives its best maize color when it has been

first dried.

The clear, crisp days of autumn are the best days of the year in

which to get brilliant colors. The statement, "Vegetable dyes are

most temperamental", may sound rather fanciful, yet it is not

unusual for two persons to employ exactly the same formula in dyeing1,

and still each gel; a different shade of color! Many factors

influence the final result, and the more carefully each process is

carried out

16 |

|

| |

14 |

the more satisfactory will the

product be. The most important points to this end are:-

1. The cleanliness of the Wool.

2. The composition of the Water used;-its hardness or softness

will affect the quantities of dye or mordant required, and receipts

must be read with this in mind.

3. The Vessels in which the wool is dyed, -brass or copper for

bright colors and iron for sober ones, after the old saying: "A

bright pot for a bright dye, a dark pot for a dark dye.''

4. The length of Time in mordanting, which process must not be

hurried.

5. The Weather, - bright colors can be gotten most satisfactorily

on a bright day.

6. The Dyes themselves, - it can almost be said that vegetable

dyes give a slightly different color for each month of the year in

which they are gathered, e. g. green walnut hulls gathered in

September give a pinkish-brown, gathered in October the pinkish

shade is gone! |

|

| |

15 |

To prepare the wool for

mordanting is the first important step in dyeing with vegetable

dyes.

All wool, when it comes from the sheep, or even after it is spun,

is very dirty and oily. The best method to clean the wool is first

to make a thick lather with some good soap that has no lye in its

composition, rubbed up in hot soft water. When the wool is put into

the cleansing bath the water should be below boiling point and so

maintained, because if the temperature reaches that point, the wool

is liable to become "fleeced", that is, matted together. Immerse the

wool in several changes of water until all the heavy lanolin has

been washed out of it, and the wool is left light and fluffy. You

will find that some wool is yellow and cannot be gotten white. This

depends on the time of year that it is sheared; the Fall shearing is

always cream color, and no amount of washing will whiten it. Dry the

wool in the open air if possible; hang it where the air can blow

through it. When the wool is thoroughly dry, carefully wrap it up

and put away from dust and dirt till it is to be dyed.

MORDANTS

While there are a few vegetable dyes that

18 |

|

| |

16 |

WASHING and MORDANTING the

WOOL

impart permanent colors to wool directly immersed in them without

any intermediary process, and which are consequently known as

"substantive dyes", most of our vegetable dyes are fugitive unless

fixed by an additional chemical agent known as a Mordant,-from the

Latin word "mordere", to bite; such dyes are known as "adjective

dyes". The application of the mordant to the wool appears to enable

the dye to bite into its substance in a manner which it cannot do

unaided.

Mordants may be applied either previous to, along with, or after

the dye bath. My own preference is to their use before dyeing,

except in such cases as where the mordant is also a saddening agent;

e. g. Copperas, which chemical not only fixes fugitive colors but

also darkens their shade. The principal mordants that I use are:-

Alum, Muriate of Tin, Bichromate of Potash, and Copperas. Several

other chemical agents are used alone or with the foregoing, such as

Cream of Tartar. Lime and Lye are often spoken of as mordants, but

since their effect appears limited to varying the brilliance or

shade of the dye it would seem better, remembering our definition of

a mordant, to class them separately, as brightening agents. Let us

see how our mordants are used.

19 |

|

| |

17 |

WASHING and MORDANTING the

WOOL

1. Alum. This is the most generally used of mordants. The best

results are gotten from alum in combination with cream of tartar:-

to one pound of wool use approximately four ounces of alum and

one-quarter ounce of cream of tartar. Too much alum would tend to

make the wool sticky. Heat the solution slowly, keeping just at the

boiling point; and don't neglect to make good the loss from

evaporation by frequently adding more water as the solution boils

away. The mordanting should go on for from a single period of one

hour to treatment extending over ten days, according to what shade

of color is wanted. For example, the best results were gotten when

mordanting for Mad-dar by boiling the wool in the solution for half

an hour each day for ten days consecutively, allowing the wool to

hang in a damp dark place between times.

2. Muriate of Tin. This is a most important mordant. By using

muriate of tin we get the most brilliant colors* It must, however,

be used with care and the proportions in the receipt not exceeded,

as its use tends to harden the wool, discoloring it slightly; used

too strong it renders it harsh and brittle. Its effect is enhanced

by addition of cream of tartar,- the proportions are, for one pound

wool, one-half

20 |

|

| |

18 |

WASHING and MORDANTING the

WOOL

ounce muriate of tin and one ounce cream of tartar. Keep the

vessel covered, have plenty of hot water and boil slowly one hour.

3. Bichromate of Potash. This mordant is most satisfactory to

use, particularly in getting yellows. The proportions are:-Wool one

pound-, Bichromate of Potash one-half ounce. To mordant thoroughly,

boil for from one to two hours in a covered vessel.

4. Copperas. Both a mordant and saddening agent. Copperas is

employed by addition to the dye bath towards the end of the dyeing

process. Not only does it darken the color of the dyed wool, it also

renders it fast; and natural grey sheeps wool can be fixed by giving

it a bath of copperas. The receipt of the old homespun weavers is "a

pinch to the pot" and this suffices. Great care must be taken to

thoroughly cleanse the pots after they have held the copperas

solution, as the least trace of it will dull the colors and spoil

the brilliancy of madder, indigo, fustic, etc.

5. Vinegar. Both a mordant and brightening agent. I only employ

vinegar when working for a rose dye from Poke berries. These give a

brown dye that is fugitive, but by immersing the wool, either before

or after

the dye bath, in a strong solution of vinegar

21 |

|

| |

19 |

WASHING and MORDANTING the

WOOL

the brown color is transformed to a beautiful rose, and this

color is fast.

BRIGHTENING AGENTS

The use of Cream of Tartar has already been alluded to. Besides

this agent Lime and Lye have been employed as giving greater

brightness to dyes. In old text-books on Oriental vegetable dyes we

find a bath of lime water used before dyeing to add brilliancy to

the colors.

Lye that has been dripped from wood ashes is most valuable in

mordanting. Old soapmakers say that the best lye is made from oak

and hickory wood ashes. These should be put into a trough or hopper,

(an old bucket with a few nail holes punched in the bottom will do

well) and rainwater allowed to drip slowly through. These drippings

will be strongly impregnated with potash which used to form an

indispensable ingredient in the days when the country housewife made

her household soap. Immersing our dyed wool in a warm bath of water

to which enough lye has been added to make it taste biting will

brighten the colors, and, in the case of Dye-flower dye, it will

change the hue from yellow to a brilliant orange, almost a red.

22 |

|

| |

20 |

DYEING

I will now give the receipts which in practice I have found to be

the most satisfactory in producing the primary colors and those

which are derived from them. By this I do not imply that it is

necessary to mix dyes to get a hue that is not a primary color. On

the contrary I would discourage recourse to the mixing of dyes where

a single one of the shade wanted is available, believing that the

latter course gives a more permanent result. For example, orange is

not a primary color, but a mixture of red and yellow ;-it could be

gotten by first dyeing with madder and afterward dyeing the red wool

in a hickory-bark bath, but I would rather use a single bath of

Dye-flower, as likely to give more lastingly satisfactory results.

Let the dyer also recall what has been said under General Remarks as

to the factors affecting the final shade given by a dye,- he will

see that it is impossible to give a formula for an exact shade of

any color, and therefore, while the receipts which follow are

appropriate for the colors under which they are listed, taste and

skill can obtain an infinite variety of shade;- in this indeed lies

both the art and joy in working with Vegetable Dyes.

I would add that in practice pale shades of a color are less

satisfactory and less enduring than full ones.

23 |

|

| |

21 |

Madder. This is a

European plant cultivated nowadays in the Netherlands, France, and

the Levant. Its botanical name is Rubia Tinc-torum. It has a yellow

flower, however the root is the portion of tha plant of value to us,

as the dye is obtained from this, dried and pulverised. Madder was

grown in former days by the mountain people of the Appalachians to

furnish dye for their homespuns. The art of cultivating the plant

and extracting the dye was evidently brought originally by them from

England, but that practice has now died out. I have found plants of

wild madder in the overgrown corners of fields that have been long

neglected. These plants yield a true madder dye, but very limited in

quantity, making the use of wild madder impractical.

Madder contains two dyes, red and brown. Shades of red are

liberated up to the boiling point, after that the brown shades are

liberated and dull the red, hence in working for Rose colors it is

most important to keep the temperature below the boiling point.

When aiming at a compound color, as Madder and Old Fustic, dye

first in madder, remove the wool from the bath and put it into a

separate bath of fustic. This is necessary as

24 |

|

| |

22 |

the

fustic requires to be boiled and the madder doesnot.

Thebrightestresultcan always begotten by adding Cream of Tartar to

the mordant.

It is better to start the wool in a cold or lukewarm dyebath and

raise the temperature gradually, to get the best color.

Brick Red.

Dissolve 4 oz Alum in 2 gals of hot water in a vessel with a

cover, put in one pound of wool and boil for two hours. Prepare

dyebath of 8 oz madder and sufficient water to well cover the wool.

Enter the mordanted wool into the cool dyebath, raise the

temperature slowly, keeping the wool moving constantly. Maintain the

heat just below boiling point for quite one and a half hours. Then

take out the wool, rinse thoroughly and dry it out of doors, hanging

it in the sun.

Crimson.

Dissolve 4 oz Alum and 1 oz Cream of Tartar in 2 gals of hot

water in a vessel with a cover, put in one pound of wool and boil

gently two hours. Prepare dyebath of 8 oz madder and sufficient

water to well cover the wool. Enter the mordanted wool into the cool

dyebath, raise the temperature slowly, keeping the wool moving

constantly. Maintain the heat just below boiling point for one hoar.

Then take out

2S |

|

| |

23 |

DYEING

the wool, rinse thoroughly and dry it out of doors, hanging it in

the sun.

Scarlet.

Dissolve 1-2 oz Muriate of Tin and 3-4 oz Cream of Tartar in 2

gals of hot water in a vessel with a cover, put in one pound of wool

and boil gently for two hours, being very careful to keep the vessel

covered. Prepare dyebath of 8 oz madder and sufficient water to well

cover the wool. Enter the mordanted wool into cool dyebath, raise

the temperature slowly, keeping the wool moving constantly. Maintain

the heat just below boiling point for half an hour. Then take out

the wool, rinse thoroughly and dry it out of doors, hanging it in

the sun.

Rosy Red from Madder.

Dissolve 4 oz Alum in 2 gals of hot water, put in one pound of

wool and boil for two hours. Take out the wool, put it in a bag and

hang it in a cool, damp place for ten days. Dampen the bag at

intervals with the alum water, in this way the wool becomes

thoroughly impregnated with the alum. Now prepare a dyebath of 8 oz

madder and sufficient water to well cover the wool. Enter the

mordanted wool into the cool dyebath, raise the temperature slowly,

keeping the wool moving constantly. Maintain the heat just below

boiling point for half an hour. Take

26 |

|

| |

24 |

DYEING

out the wool, rinse thoroughly and dry it out of doors, hanging

it where the sun shines.

In all these receipts a variety of shades may be gotten by

varying the time that the wool is left in the dyebath, however the

paler shades are apt to be fugitive.

Cochineal.

Cochineal is a dyestuf f consisting of the dried bodies of female

insects found on the underside of leaves of several species of

cacti, native in Mexico and Central America. These cacti are

extensively cultivated for the purpose of raising the insects, which

are periodically gathered and killed by heat.

Cochineal when bought from the chemist sometimes looks silvery

and sometimes black. Either kind is equally good for dyeing, the

differing appearance being due to the mode in which the insects were

killed, those killed in stoves retain the natural white powdery

covering, and silver-grey cochineal results; when killed by steam or

hot water the insects lose this covering, and black cochineal is

produced.

Crimson from Cochineal.

Dissolve 21-2 oz Alum and 11-2 oz Cream of Tartar in 2 gals of

water in a vessel with a cover. Put in one pound of wool and boil

for two hours. Prepare dyebath of 1 oz cochineal in

27 |

|

| |

25 |

DYEING

two gallons of water. Enter the mordanted wool into the dyebath,

raise the temperature slowly, moving the wool constantly. Boil for

two hours. Take out, rinse, and dry the wool in the sun.

Scarlet from Cochineal.

Mordant the wool for two hours in a vessel with a cover, 1-2 oz

Muriate of Tin and 3-4 oz Cream of Tartar in two gals of water for

one pound wool. Be careful to keep vessel covered. Prepare dyebath

of 2 oz Cochineal in enough water to well cover the wool, enter the

wool when the dyebath is warm and raise gradually to the boiling

point. Boil for an hour, keeping wool moved about at intervals.

Remove wool, rinse it in clear water and dry in sunshine.

Kermes.

This dye is of the same nature as cochineal, that is to say. it

consists of the dried bodies of the female of certain scale insects,

which are parasites of several species of oak, especially an oak of

the Mediterranean region. They are round, about the size of a pea,

and contain coloring matter analagous to carmine. Kermes is still

used in Turkey, Morocco, etc; it is considered by most dyers to be

the best of all red dyes; Kermes was in use in Europe in the tenth

century and the old Gothic tapestries were dyed with it. These on

comparison with the later,

28 |

|

| |

26 |

DYEING

Cochineal dyed tapestries prove its superiority both for shade

and permanence.

Red from Kermes.

Mordant the wool(l lb)with 3 oz Alum and 2 oz Cream of Tartar,

boiling it for two and a half hours. Take the wool out of the

mordant, wring out gently, saturate with "sour-water" (i. e., water

in which wheat bran has been allowed to ferment), put it into a bag

and leave it in a cool place for five days, moistening it

occasionally with the sour-water. Then dye in a bath of 10 oz Kermes

in 2 gallons of water.

Poke Weed. (Phytolacca Decandra.)

This is a coarse American perennial herb with racemose white

flowers and dark purple, juicy berries which latter yield a

beautiful rosy-red dye.

Rose-red from Pokeberries.

Mordant the wool with 2 gals water and half-gallon strong Vinegar

(for 1 Ib wool). Boil for one hour. Prepare dyebath with 2 gals of

the juice of ripe Pokeberries and 1-4 gal strong vinegar. Enter the

wool and simmer for one hour in a copper pot. Take out the wool and

let it drip a while. Dry in the sun. Afterwards wash and dry again

in the sun.

Sorrel. (Rumex Acedosa.)

A well known American wildflower. Its

29 |

|

| |

27 |

roots and stalks yield a

reddish dye.

Red from Sorrel.

Mordant the wool with Alum, 4 oz Alum in 2 gals water. Boil 1 Ib

wool in the mordant for two hours. Transfer the wool to the copper

dyepot, cover it with 2 gallons of water and to this add half a peck

of well-washed Sorrel, roots or stalks, in sufficient amount to make

a strong ooze. Boil slowly for one hour, take out the wool, rinse,

and dry in the sun. This will give a pale red.

Red Poppies, (genus Papava.)

A well known annual garden flower, the heads of which yield a

purplish red dye.

Red from Red Poppy.

Take a sufficiency of Red Poppy heads to make a strong ooze.

Mordant the wool with Alum (4 oz Alum in 2 gals water to 1 Ib wool)

for one hour, then transfer it to the ooze and dye at boiling point

for say a half-hour, or until the color satisfies. The best results

are gotten when the poppy heads are picked fresh and put at once to

use.

Other plants, and vegetable substances such as lichens, give red

dyes. The individual craftsman is urged to experiment with those

whose names follow here, this list has been gotten from various

sources, and there is a vast

30 |

|

| |

28 |

DYEING

field for research in trying out new mordants for many of them.

Birch. Fresh inner bark.

St. Johns Wort. Leaves

Wild Madder.

Red Root (Creanothus Am.).

Red Lobelia (L. Cardinalis).

Blood Root.

Red Oak. Bark.

Hemlock. Bark.

Potentil. Roots.

The Lichen, Ramalina Scopulorum.

The Lichen, Parmelia Omphalodes, or

"Black Crottle." The Lichen, Lecanora Tartarea, or Crotal.

31 |

|

| |

29 |

DYEING

YELLOW

Nature has supplied us so liberally with material for the Yellow

dye that we may well feel at a loss in making a choice. Hickory,

Black Oak, and Crab-apple Barks; Sedge Grass and Cockle Burrs;

Privet and Sweet Laurel Leaves; Marigold, Dye Flower, and Goldenrod,

all yield up their store of golden sunshine when suitably treated in

the dyepot.

They must all be subjected to the action of either Alum or acid

of some kind to properly impart their essence to the material to be

dyed, and just in proportion to the strength of the acid used in the

mordant will be the fullness and richness of the resultant yellow

tones.

Mathew Atkinson in his "Family Director, 1844" remarks "among all

the materials af^ fording the color Yellow there is perhaps none

cheaper or better adapted to general use in dyeing than the Black

Oak bark, as it imparts, when properly applied, every variety of

shade, with all the richness of which the yellow dye is

susceptible."

Black Oak Bark(Quercus nigra). A species of Oak native to North

and Central America. The inner bark is the source of the dye, and,

powdered, is sold as "Quercitron", the active principle of this

powder is a yellow, crystalline

32 |

|

| |

30 |

DYEING

substance Quercetin, which may be bought under the name

"Flavine". If it is desired to use the crude bark in dyeing some

care should be used in selecting the tree from which it is to be

stripped. A trial incision may be made in several trees and the one

whose inner bark appears most yellow chosen. The bark is best

stripped in May, and on removal it should be cleared of all outer

dead bark, retaining for use that part only which is soft and

growing. This should be carefully put away from dirt and damp in an

airy place until it is fully dried, then reduced to fine powder. It

will pulverise easily.

Yellow from Black Oak Bark.

Dissolve 4 oz Alum and 2 oz Cream of Tartar in 2 gallons of

water. Put in one pound of wool and boil for two hours. Prepare

dyebath of 4 oz powdered Black Oak Bark in 2 gallons of water,

transfer the mordanted wool (without rinsing) to the dyebath and

boil until the color appears of sufficient depth. Addition of a

small quantity of powdered chalk towards the end of boiling will

brighten the color.

Orange-yellow from Black Oak Bark.

In two gallons of water dissolve 2 oz Cream of Tartar and 1-2 oz

Muriate of Tin. Pat in one pound of wool, cover the vessel and boil

for one hour. Prepare dyebath of 4 oz powdered Black

33 |

|

| |

31 |

DYEING

Oak Bark in two gallons of water. Transfer the mordanted wool,

without rinsing, and boil until the desired color is obtained.

Old Fustic.

What Madder is among the red dyes Old Fustic is among the

yellows. Called Old Fustic to distinguish it from Fustet or Young

Fustic, the Cockspur Thorn, it is more often referred to simply as

Fustic. This dyewood is native to Mexico, Jamaica, and other

subtropical countries, its scientific name is Chlorophora Tinctoria

and it is a relative of the mulberry. It yields a bright yellow dye,

which is extracted from the heart-wood of the tree. The extract is

found to contain two coloring principles, Morin and Maclurin, they

both give yellow.

Yellow from Fustic.

Dissolve 1-2 oz Muriate of Tin and 3-4 oz Cream of Tartar in 2

gallons water in a covered vessel. Mordant one pound of wool in this

for half an hour, keeping vessel closed. Prepare a dyebath with from

2 to 6 oz of Fustic Chips, (according to depth of color desired).

Transfer the mordanted wool to the dyebath. Boil till color pleases,

but for an hour at least. Very long boiling tends to green it.

Old Gold from Fustic.

Mordant 1 Ib wool in 2 gallons water with

34 |

|

| |

32 |

DYEING

1-2 oz Bichromate of Potash and 1-2 oz Cream of Tartar. Simmer

for an hour. Prepare dyebath of from 2 to 6 oz of Fustic Chips in 2

gals water. Transfer the mordanted wool to the dyebath and boil till

the shade desired is reached.

Lemon Yellow from Fustic.

Dissolve 4oz Alum and 1 oz Cream of Tartar in 2 gals water. Enter

1 Ib wool into this solution, simmer for 3 hours. Prepare dyebath of

4 to 6 oz Fustic Chips in 2 gals water. Boil for an hour to extract

the dye, then enter mordanted wool and boil slowly for one hour.

Sedge Grass (a plant of the genus Carex).

This grass yields a clear yellow dye. For this purpose it is best

gathered after it has become dry in the autumn. It is then easily

found, as it grows freely over unimproved pasture land and its

erect, strawcolored stems are left untouched by the grazing cattle.

Bright Yellow from Sedge Grass.

Dissolve 1-2 oz Muriate of Tin and 1-2 oz Cream of Tartar in a

covered vessel containing 2 gals water. Enter 1 Ib wool and simmer

slowly for 3 hours. Prepare dyebath of half a bushel Sedge Grass, or

enough to make a strong ooze, in 3 gals water. This ooze should be

of a clear, brownish color. Transfer the mordanted wool to this

dyebath and boil slowly for half an hour.

35 |

|

| |

33 |

Golden Yellow from Sedge

Grass.

Dissolve 4 oz of Alum and 1-4 oz Cream of Tartar in 2 gals water.

In this mordant lib wool for 4 hours. Take vessel from fire and

allow to cool without removing wool. Prepare dyebath of 3 or 4 gals

water and enough Sedge Grass to make a strong ooze. After wool has

become cold in the mordant transfer it to sedge-grass dye-bath, and

simmer slowly until desired color is obtained; this is a beautiful

and lasting dye.

Old Gold from Sedge Grass.

Mordant the wool, using 1-2 oz Bichromate of Potash to 1 Ib wool

in 2 gals water. Simmer for one hour. Then transfer to a strong

ooze, j prepared as before and simmer till the desired shade is

reached. Rinse and hang in sun to dry; this applies to all Sedge

Grass receipts.

Maize from Sedge Grass,

Mordant 1 Ib wool with 4 oz Alum and sufficient water. Prepare

dyebath with 1-2 bu Sedge Grass. Enter mordanted wool; simmer twenty

minutes, or until a straw-like shade is obtained.

Hickory.

The bark of this well-known North American tree yields a yellow

dye. The inner bark contains the coloring matter and may be used for

dyeing at any time except spring, when the risingsap weakens its

efficacy for that purpose.

36 |

|

| |

34 |

DYEING

Greenish-yellow from Hickory Bark.

For 1 Ib wool, dissolve 4 oz Alum in 2 gals water. Mordant for 4

hours, and allow the wool to cool in the liquid. Prepare a dyebath

of 1-2 bushel fresh inner bark of the Hickory. Boil the bark in 2

gals water until a strong ooze of a clear brownish-yellow color is

obtained. Transfer the mordanted wool to dyebath and boil for an

hour; then add a small quantity of hickory buds, continue boiling

for another half-hoar, rinse and hang in sun to dry.

Deep Yellow from Hickory Bark.

Mordant 1 Ib wool in 2 gals water in covered vessel with 1-2 oz

Bichromate of Potash and 1-2 oz Cream of Tartar for one hour.

Prepare dye-bath with sufficiency of hickory bark to make a very

strong ooze. Immerse the mordanted wool in this and boil until the

desired color is obtained. Pale shades with Hickory bark are not

lasting or satisfactory.

A still brighter yellow can be gotten with Muriate of'Tin and

Cream of Tartar as mordants.

Hickory Bark is often used to turn wool green after it has been

dyed with Indigo (see "Green").

"Dyeflower." A species of Coreopsis. A small, wild flower growing

freely on the hillsides in the Appalachians and adjacent country

37 |

|

| |

35 |

DYEING

side as far north as New Jersey. It blooms profusely all summer.

An extract from the blossoms gives a most beautiful yellow dye.

Golden-yellow from Dyeflower.

Mordant 1 Ib wool with 4 oz Alum and 1 oz Cream of Tartar in 2

gals of water for an hour. Prepare a dyebath of 2 gals water into

which a peck or so of dyeflower heads has been thrown. Transfer

mordanted wool to the cool dyebath and raise temperature quickly to

boiling point. Continue boiling till the desired color is gotten,

remembering that too prolonged boiling will dull the color.

Brilliant Yellow from Dyeflower.

Dissolve 1-2 oz Muriate of Tin and 1-2 oz Cream of Tartar in 2

gals water. In this mordant 1 Ib wool for half an hour, keeping

vessel covered mean while. Prepare dyebath of about a peck dyeflower

heads in 2 gals water. Transfer mordanted wool without rinsingto the

dyebath. Bring quickly to a boil and keep at boiling point until the

desired color is obtained. Prolonged boiling will dull the shades.

Deep Yellow from Dyeflower. Dissolve 1-2 oz Bichromate of Potash

in 2 gallons water. Into this mordant put 1 Ib wool and boil for two

hours being careful to keep the vessel covered. Prepare dyebath of

one peck of dye-

38 |

|

| |

36 |

DYEING

flower heads in 2 gals water, put in mordanted wool, and boil for

twenty minutes, stirring constantly, and airing the wool at

intervals. Rinse and hang in the sun to dry.

Marigold (An Asteraceous plant of the genus Tagetes). Any of the

species gives a dye, but the African Marigold is the best to use in

the dyepot. The heads may be used freshly gathered or dry, but best

results are gotten with fresh ones. The color obtained with

Marigolds is especially beautiful, being exactly that of the

blossoms. It is also permanent, provided that the mordanting be

carried out thoroughly. During the dyeing process it is fascinating

to watch the transference of the color from the flowers to the wool.

On putting the blossoms into the dyepot and adding the mordanted

wool the golden color can be seen to leave the flowers and go into

the wool under our very eyes.

Marigold-yellow from Marigold.

Mordant 1 Ib wool in 2 gals water with 4 oz Alum and 2 oz Cream

of Tartar. Boil for two hours in covered vessel. Remove from fire

and allow wool to cool in mordant. Prepare dyebath of 2 gals water

and a peck or so of Marigold heads. Transfer mordanted wool to the

dyepot, which has been raised to the boiling point. Stir constantly

and air wool at interval. Continue

39 |

|

| |

37 |

DYEING

only so long as necessary to get the desired color. Remove from

dyebath and dry in sun without rinsing. Later, rinse and again dry

in the sun.

Varying shades can be gotten with Marigolds by use of other

mordants in proportions already given.

Coreopsis (Coreopsis Tinctoria.)

A wellknown garden flower with yellow blooms. The heads may be

used for dyeing either gathered fresh in the summertime or may be

stored away for use in winter or spring.

Golden-yellow from Coreopsis.

Dissolve 1-2 oz Muriate of Tin and 2 03 Cream of Tartar in 2 gals

water. In this mordant 1 Ib wool for one hour keeping the vessel

covered. Prepare dyebath of 2 gals water and a peck or so of yellow

Coreopsis heads. Transfer mordanted wool, without rinsing, to

dyebath, which has been already raised to boiling point. Boil for

twenty minutes, airing wool occasionally. So soon as the color

pleases remove wool and, after rinsing, hang in the sun to dry.

Sometimes transferring the wool, after dyeing, to a bath of strong

suds made from a good quality of washing soap, and rinsing it

therein, will improve the color.

Various shades can be gotten with Coreopsis

4O |

|

| |

38 |

DYEING

by the use of other mordants, in the proportions already given.

Cockle Burr, or Agrimony.

A common weed with hairy stem, and small, inconspicuous, yellow

flower. The seeds are covered with little hooked spines and adhere

tenaciously to any rough-coated passerby. The leaves and stalk yield

a yellow dye.

Gold from Cockle Burr.

In 2 gals water make a weak solution of Bismuth, and in this

mordant the wool for an hour in a closed vessel. Transfer the wool

to a dyebath made up with 2 gals water and about a peck of fresh

leaves and stalks of the Cockle Burr. Boil until the desired color

is obtained. Then rinse, and hang in the sun to dry.

Privet (Ligustum Vulgare).

The leaves of this well-known oleaceous shrub yield a yellow dye.

Yellow from Privet Leaves.

Mordant 1 Ib wool with 3 oz Alum and 1 oz Cream of Tartar in 2

gals water for two hours. Prepare dyebath of 2 gals water and a peck

of Privet leaves, to which transfer mordanted wool, and boil until

the color pleases. This gives a good yellow.

Golden-Rod (Solidago).

There are many varieties of golden-rod,

41

|

|

| |

39 |

DYEING

dye may be gotten from the variety known as Dyers Weed,or Grey

Golden-rod (S.Nemoralis). Mordant 1 Ib wool with 4 oz Alum and 2 oz

Cream of Tartar in 2 gals water, boil for an hour, take out the wool

and hang in a bag in a cool place. Keep it so for ten days,

dampening it occasionally with the mordant. Then prepare a dyebath

of 2 gals water in which a peck or so of the heads and tender stalks

of Golden-rod have been boiled until a good stbng ooze is extracted.

Immerse the mordanted wool and boil till the desired color is

obtained. This gives a good, lively yellow.

Osage Orange (Toxylon Pomiferum).

An ornamental American moreaceous tree, allied to the Mulberry.

It was first found in the country of the Osage Indians, who employed

its wood to make bows and arrows, as well as to dye their war

bonnets, etc. The tree bears a yellow, apple-shaped fruit; it grows

in south Arkansas, Oklahoma, and Texas, and attains a height of 50

feet with a diameter of 2 feet. In the South-West an extract of the

roots and bark is made by boiling, and used as a dye. Like Fustic,

the heart wood contains two coloring principles, Morin and

Maclurin,and it has been urged that it be substituted for the former

wood for dyeing purposes; it is claimed to be a

42 |

|

| |

40 |

DYEING

faster dye than Fustic, cheaper, and a native product instead of

an import.

Osage Orange extract is marketed under the name "Aurantine". For

its use to produce various Yellow shades, the receipts given under

Fustic may be followed.

Crab Apple. The inner bark of this wild fruit tree yields a

yellow dye.

Yellow from Crab Apple.

Mordant 1 Ib wool in 2 gals water, in which has been dissolved 4

oz Alum and 1 oz Cream of Tartar. Boil for two hours. Prepare

dyebath of 2 gals water and enough crab-apple bark, freshly

stripped, to make a strong ooze. Transfer the mordanted wool to the

dyebath, and boil till the desired color is obtained.

Nettle. Plants of the genus Urtica.

The tops yield a yellow dye. Thorough mordanting is essential

with this, as with all yellow vegetable dyes.

Yellow from Nettles.

Mordant 1 Ib wool in 2 gals water with 4 oz Alum for two hours.

Prepare a dyebath with 2 gals water and a sufficiency of nettles to

make a strong ooze. Immerse the mordanted wool and boil until the

desired shade is obtained.

Sweet Leaf, Horse Sugar, or Dye Bush. (Symplocus Tinctoria.) In

early spring the

43 |

|

| |

41 |

DYEING

bush of this name has clusters of intensely yellow, fragrant

flowers on the bare twigs, except in the deep South, where the

leaves remain on the tree all winter. These leaves are yellow-green,

bright, and have a silvery sheen. If dried the color becomes more

intense. The leaves are used to make a yellow dye. Yellow from Dye

Bush. Mordant 1 Ib wool with 1-2 oz Muriate of Tin and 2 oz Cream of

Tartar in a covered vessel for an hour. Have ready a peck of Dye

Bush leaves, and 2 gals of boiling water in the dyepot. Transfer

mordanted wool to the dyepot and add thereto the leaves. Boil for

three-quarters of an hour. Remove, rinse, and hang in sun to dry.

Other vegetable sources credited with yielding a yellow dye are

the following:

Willow. Leaves.

Hornbeam, or Ironwood. (Carpinus Beludus.)

Marsh Marigold.

Meadow Rue.

Buckthorn. Berries and bark (Rhomnus frangula.)

Barberry. Stems and roots.

Venetian Sumac, or Smoke Tree. (Extract, "Fustine".)

American Smoke Tree, or Chittam Wood.

Clematis. Leaves and branches.

|

|

| |

42 |

DYEING .

Ash. Fresh inner bark.

Sundew. (Drosera Rotundifolia.)

Lombardy Poplar. Leaves.

Pear. Leaves.

Plum. Leaves. .:

Tulip tree. Leaves.

St. Johns Wort. Flowers.

Ragweed.

Cynara. Artichoke.

Hops.

Rye.

Birch. Leaves.

Broom.

Tomato-vines.

Bog Myrtle.

Bramble.

Common Dock. Root.

Burdock.

Orange Root, or Golden Seal. (Hydrastis

Canadensis.)

Black Gum, or Tupelo. Bark. Spindle tree. (Euonymus Atropureus.)

Gorse. Bark, flowers, and young shoots. American or Kentucky Yellow

Wood.

(Cladrastis Lutea.) Pointed-Leaf Tick Trefoil. (Meibomia

Grandiflora.)

45 |

|

| 46 |

43 |

DYEING

BLUE

Indigo. This dye is the product of the plant Indigofera Tinctora,

largely cultivated in India, China, Guatamala, etc. For a time

Indigo was successfully grown in South Carolina and other southern

states, but has now entirely passed out of cultivation there.

The coloring matter does not exist as Indigo in the plant, but

develops when the freshly-cut plants are suitably treated. The

method employed is to throw them into vats of water, where they are

steeped for some time. The liquid is then drawn off into another

mixing vat, and there stirred till it assumes adeep purple color. It

is then left to stand until the sediment has been deposited. This is

afterwards removed, boiled, strained, and dried in a form suitable

for market. Usually it is sold in lump form, which is insoluble in

water, even when powdered, hence various means have to be employed

to fit Indigo for the dyebath.

To produce the best quality Indigo requires evidently a high

degree of skill.

There is an indigenous wild Indigo, (Bap-tesia Tinctoria) found

in the United States of America. It is a smooth, slender plant, with

deep grey-green leaves and small, pea-like

46 |

|

| 47 |

44 |

DYEING,

blossoms of pure yellow. This plant is to be found in great

abundance along the sides of the Appalachian Mountains; it may be

recognized by the peculiar property of its leaves, which turn black

on withering.

Preparation of dye material from Baptesia Tinctoria.

The Oldtime way of obtaining coloring matter from the Wild Indigo

was as follows: Pack the plant in a barrel and pour water over it.

Leave it to ferment, which it will probably do in a couple of days,

then squeeze out the plant and churn the liquor, then add lye from

oak-wood ashes until precipitation of dye occurs. To help this

result, bruise and soak some Red Sumac, and add the liquid from this

to the extract. When this becomes clear pour off the fluid and the

dye material will be found as sediment in the barrel.

To prepare Indigo for dyeing, three methods may be given: First,

the old-fashioned Indigo vat; second, Indigo Extract (Saxon Blue);

and last, the Soda-hydrosulphite vat. For setting up the Indigo vat,

or Blue Pot, many receipts exist. From these I have chosen a

mountain dyer's as follows: Place an iron kettle, capable of holding

at least five gallons, where it can be kept warm for several days,

as

47 |

|

| 48 |

45 |

DYEING

on the hearthstone. Mix a pint of Madder with a pint of

wheat-bran, just moisten this, then put it at the bottom of the

kettle with a china plate over it. Now pour into the kettle two

gallons of warm water and one pint of lye dripped from wood ashes.

Tie 4 oz of good Indigo in a thick cloth, and suspend it in the

kettle. When it is soft, rub out the dye. If possible procure the

blue yeast from some other Blue-pot and add this to the kettle,

otherwise put in a cake of yeast.

Keep the vessel covered and warm, just luke warm, for four or

five days, when it will be ready for use. Experienced dyers can tell

when the dyepot is ready for the yarn by the smell of the solution.

This will be coated with a violet colored, lustrous film, and the

liquid, if poured from a spoon, will be clear, of a greenish-yellow

shade. Its condition for dyeing can be tested by dipping a small

hank of yarn, leaving it in a few minutes and then seeing if the

color has "taken" on the yarn at all. Shades from pale blue onward

can be gotten by repeated dipping and airing the yarn, remembering

that it is the oxidizing of the coloring matter in the air that sets

the color imparted in the pot.

For very dark blues it may be needful to

48 |

|

| 49 |

46 |

DYEING

leave the yarn in the pot for several hours, then air without

rinsing for a like period. The yarn should of course be thoroughly

washed when the right shade has been reached.

Saxon Blue.

To prepare the Indigo. Take a quarter pound of finely ground

Madras Indigo and one and a quarter pounds of strong Sulphuric acid.

Mix them well together in a deep earthenware or glass vessel of at

least one gallon capacity. When the Indigo is thoroughly

incorporated with the acid, stir in very slowly one-half ounce of

common salt. A thin, flat piece of wood can be used for stirring. Be

careful not to splash any of the mixture on the hands or clothes,

and this should be done out of doors or on an open porch, as strong

fumes are evolved. Continue to stir for at least five minutes, and

at intervals thereafter for at least an hour, covering the vessel

between times with paper or an old cloth. The mixture will at first

form a hot, bubbling mass, bat will settle down after a while. Set

aside in a dry place, and repeat the stirring at intervals during

the next three or four days. After this, if no more fumes are given

off, the dye is ready for use. It should be kept covered, and stored

in a dry cupboard, otherwise it will absorb moisture from the air,

|

|

| 50 |

47 |

DYEING

and become weaker.

To Dye, Use a brass or enamel pot of about six quarts capacity.

Fill three-quarters full and place on the fire. With a wooden spoon

or spatula take out a half-teaspoonful of the dye (which should now

be in the form of a thin paste), add to the bath, and bring to

boiling point. The wool to be dyed should be at hand, already well

wetted in warm water. Take it up on a smooth stick, or long-handled

wooden spoon, and put it quickly into the dyebath. One or two hanks

may be entered at the same time, they must be moved about, to ensure

all parts being equally brought into contact with the dye. Lift and

air several times, continuing to heat the pot till it boils. After

boiling a few minutes lift the yarn and note the color as to shade

desired. With this process the color is taken up much more rapidly

and completely than it is with the Vat method, hence the need for

care in quickly getting the wool into the bath, and in contact with

the dye, to avoid uneven dyeing. When the liquid which runs from the

yarn as it is aired becomes nearly colorless the wool has reached as

dark a shade as that dyebath will produce. To get a darker shade,

remove the wool from dye bath whilst adding more dye,

50 |

|

| 51 |

48 |

DYEING

stir this in well and quickly re-enter the yarn; this will ensure

an even color, free from streaks or light patches. When the yarn is

as dark as wanted, continue to boil for fifteen minutes. Rinse

thoroughly. A little Bicarbonate of Soda in the washing water

towards the last will neutralize any remaining acid in the wool.

Hydrosulphite-Soda Vat. This method is the most modern way of

dyeing with Indigo, it can be used either with the natural or

synthetic product. It produces a pleasing and fast blue. All shades,

from light to dark blue, can be gotten by varying the length of time

and number of dips that the wool is given in the dye vat. It does

require care in mixing and testing the solutions used, but,

given reasonable care, results can be depended on. The ingredients

are:

1 oz powdered Indigo.

1 oz Hydrosulphite of Soda.

1 & 1-2 oz Caustic Soda (Sodium Hydroxite). Apparatus needed

consists of a glass measuring vessel, graduated in ounces. A glass

stirring rod. A Hydrometer, such as is used for testing electric

storage batteries. A pasteurising thermometer.

51 |

|

| 52 |

49 |

DYEING

To make the Stock Solution we must make two preliminary

solutions.

1. Into a glass or enamel vessel of sufficient size, measure six

ounces of tepid water. Gradually add to this the whole of the

Caustic Soda, stirring the while, and being careful not to splash

the liquid onto hands or face. It will heat considerably; set it

aside to cool.

2. Into a half-gallon pitcher, measure forty ounces of tepid

water. To this add gradually the Hydrosulphite, stirring the while.

Rub up the Indigo with a little warm water, making a thin paste. Now

check the Caustic Soda solution with the Hydrometer, it should read

between 1150 & 1200 on the scale (that is, it should be of

approximately 1.175 sp. gr.) Take three-and-a-half ounces of this

solution and stir it very slowly into the rubbed-up Indigo. When it

is thoroughly combined, measure off twenty-seven ounces of the

Hydrosulphite solution and stir it slowly into the Indigo and

Caustic Soda mixture. This is the Stock solution for dyeing; it

should be heated slowly to around 125 P., and left to stand for half

an hour, before use.

To set the vat. Use a brass or enamel vessel of three or four

gallons capacity. Fill three-quarters full of water at 125 deg. F.

52 |

|

| 53 |

50 |

DYEING

Add to this three or four ounces of Solution No. 2 - this is to

de-oxygenate the bath. Let it stand for a quarter hour. Meanwhile

check the Stock Solution for correct condition, as follows: Dip the

glass stirring- rod and withdraw it. The liquid on it should be a

clear greenish yellow, changing quickly to blue. If the glass is

covered as it is withdrawn with blue patches, these indicate

undissolved Indigo, and call for addition of more of the No.2

solution (Hydrosulphite) - say two ounces.

On the other hand, a thick, milky appearance of the stock

solution calls for the addition of a little caustic soda solution.

In either case, if correction is needed, give the added chemical

time to function. However, given care in the first mixing and

measuring, the stock solution will probably need no additions.

To Dye. Measure off an ounce of the stock solution and stir it

into the dyebath, take care not to make many bubbles in so doing.

Set the dye pot over low heat and bring to 125 deg. F. Enter the

wool, previously wetted, move it around at intervals. After some

minutes lift the wool and note the color. It should be a

yellowish-green, changing on exposure to blue. Continue dyeing for

fifteen minutes, then lift and air for the same length of time. If

not

53 |

|

| 54 |

51 |

DYEING

dark enough, replace the wool in the dyebath, first adding a

little stock solution, and repeat the alternate dyeing and airing

until the color satisfies. Repeated immersions in the dyebath give a

better deep shade of blue than the use of a stronger bath will

produce. That is, the dyeing cannot be hurried, and still give the

best results. Remember to keep a watch on the temperature, this must

never exceed 140 deg. F., around 130 deg. F. is safe and effective.

Finally wash thoroughly, passing the wool through a weak solution of

sulphuric acid - a few drops to a gallon of water - during the

process, to neutralize any caustic left in it.

Simplified method for Blue with Hydro-suphite and Caustic Soda.

The chief danger in dyeing with the foregoing method is possible

damage to the wool by the caustic soda in the bath, too much will

make the bath feel slimy, and its effect is to reduce the wool to a

rubbery consistency. To preclude failure from this cause commercial

chemists have produced a sensitized tape, by which the strength of

the soda solution can be checked. This tape, called Phydrion Paper

(B), changes shade when dipped into the caustic soda bath, varying

with the strength of the solution, and its color can be compared to

a

54 |

|

| 55 |

52 |

DYEING

scale shown on the little box in which the tape is put up. The

tape can be obtained from the Scientific Glass Apparatus Corporation

of Bloomfield, New Jersey.

To dye by this method, first boil up three to five gallons of

water in the dyepot. Continue boiling for half an hour, to drive off

all air held in suspension, then let the water cool to 120 deg. F.

Now slowly stir in caustic soda, a little at a time, dipping

fragments of the test tape at intervals, and comparing the shade to

the tints of the scale. When the reading is between 7 & 9 the

strength is correct. Now weigh out equal amounts of Indigo and

Hydro-sulphite, say one-half ounce of each. Rub the powdered Indigo

up with a little water, to make it mix easily and stir it into the

caustic soda bath. Then gradually stir in the Hydro-sulphite; let

stand ten minutes, gradually warming the bath to 125 deg. F. - not

over 140 F. Enter the wool, dye according to directions already

given for alternate dyeing and airing, etc. After washing, and an

acid bath to remove any remaining caustic soda, pass through a very

hot soapsud solution, using a mild soap, such as Ivory flakes for

this, then rinse and hang out to dry.

The resulting color by this method is a

55 |

|

| 56 |

53 |

DYEING

very beautiful blue, and, because of its fastness, it should

always be employed when it constitutes the first step towards

producing green shades. In my opinion, however, it does not entirely

supercede the Saxon Blue method, as the shades of blue gotten by

that process have an unique charm of their own.

Slate Blue from Logwood.

Mordant one pound of wool in a covered vessel with half an ounce

of Bichromate of Potash, dissolved in sufficient water. Boil for an

hour, remove and rinse. While the wool is mordanting make a strong

ooze with Logwood chips in three gallons of water; strain out the

chips and add one-half ounce chalk. Enter the mordanted wool and

boil for an hour, at intervals raising and airing the wool. Then

wash and hang out to dry.

56 |

|

| 57 |

54 |

DYEING

GREEN.

Green is perhaps the least satisfactory of all vegetable dyes, so

far as fastness is concerned. To get a good green, dye the wool

first with Indigo, using preferably the Hydrosul-phite method. Then

put the blue yarn through an alum mordant, and green it in a yellow

dyebath. For this there is a large choice, - Old Fustic. Sedgegrass,

Hickory bark, etc.

The depth of color produced by the initial dyeing must depend on

the shade of green which the dyer desires as the final result of his

or her work. If a blue-green is wanted, then the yarn should be dyed

a deep blue first, and finished in a weak or normal yellow ooze. If

on the other hand a yellow-green is the objective, dye a pale or

medium blue, and finish in a strong yellow dyebath. Exact directions

cannot take the place of experience and judgment, the dyer must have

in mind just what she desires as the goal of her work, and persevere

to that end.

Green with Lily-of-the-Valley Leaves.

A fairly good green can be gotten from a few vegetable sources.

Young Lily-of-the-Valley leaves will give a delicate, fairly fast

green. For one pound of wool use four ounces of Alum, and mordant

for an hour. Prepare

57 |

|

| 58 |

55 |

DYEING

the dyebath with a peck of young Lily-of-the-Valley leaves,

boiling them until they have colored the ooze. Transfer the wool to

the dyebath, without rinsing, and boil for an hour.

Bottle-Green with Logwood.

Mordant one pound of wool in a covered vessel with one-half ounce

of Bichromate of Potash for an hour. Remove and rinse.

Prepare a strong ooze with Logwood chips in three gallons of

water. Strain out the chips and add one-half ounce chalk to the

ooze. Enter the mordanted wool and boil for an hour, lifting and

airing it at intervals. The resulting color should be a dark slaty

blue. Rinse and transfer to a dyebath of Old Fustic. For this, make

up a strong ooze, either by boiling Old Fustic chips, or dissolving

the prepared crystals. Use a part of this to form the dyebath, of

medium strength; enter the dyed wool and boil for ten minutes; lift,

air, and rinse. Examine in the light for color. If not satisfactory,

add some of the Old Fustic ooze to the dye-bath, return the wool and

boil again. Continue this process till the color pleases. Boiling

time in the Old Fustic bath should total at least one-half hour.

58 |

|

| 59 |

56 |

BROWN.

The most dependable source of our brown dye is the Black Walnut,

and wherever that tree flourishes the dyer will look to it for most

of the shades of brown which he or she has need for. Bark, roots,

and the hulls protecting the nuts are alike rich in the dyeing

material, but, since the black walnut is a valuable tree, we shall

not consider the use of either bark or roots, for equally good

results can be obtained from the hulls, an annual waste product at

the time of harvesting the nuts.

Brown from Walnut Hulls.

This is a substantive dye, and needs no mordant. Boil up half a

peck of hulls in three gallons of water, in an iron pot. Enter the

wool, moving it round till it is all equally wetted by the dye, and

boil for a length of time depending on the depth of color desired.

For a pale tan boil for a few minutes only; for darker shades

continue boiling for from ten minutes to an hour or more. This gives

a warm, rich brown, fast to light and washing.

To get a very dark brown add a pinch of copperas and a double

handful of sumac berries. Simmer the wool in this for an hour or

more and leave it in the ooze overnight. Then rinse very thoroughly,

both the wool and the

59 |

|

| |

57 |

DYEING

dyepot before it is used for other work.

A pinkish brown can be gotten from the green hulls, when they are

first stripped from the nuts in the Fall. Hulls for later use must

be spread out and dried thoroughly before being bagged and hung up

for use througout the year.

Brown from Sumac.

Another shade of brown can be gotten with sumac berries alone,

gathered after they have turned red and boiled up in a brass or

enamel pot. This also is a pleasing shade of brown, with a greenish

tinge, and very fast. All depths of color, from tan to dark brown,

can be gotten, depending on strength of ooze and length of time for

which the wool is boiled therein.

Brown from Black Walnut Leaves.

In the fall a delicate shade of brown can be gotten as follows:

Gather a peck of Black Walnut leaves. Having cleaned the pot

thoroughly put a layer of these leaves in the bottom, then a layer

of wool yarn on these, then another layer of leaves, and so on

alternately. Pour in enough "fair water"to cover all. Then cover the

pot and set aside for about a week, after which time remove and

rinse the yarn. It will be found dyed a pleasing light shade of

brown.

6O |

|

| |

58 |

DYEING

BLACK.

A good black can be gotten from Walnut (either hulls, bark, or

root) in combination with Sumac. White Walnut gives the best

results.

Use the hulls to make a strong ooze, as when dyeing brown, but

put in a larger quantity in your iron pot, with three or four

gallons of water. Start a brisk fire under the pot and when it boils

add a double handful of sumac berries and a tablespoonful of

copperas. So soon as the last is dissolved enter the wool. Simmer

over a slow fire all day. Leave overnight in the dyepot and continue

simmering next day. The process should go on for at least

twenty-four hours in all. At the end of that time let the fire die

out, but leave the yarn in the dyepot until it has become cold. Then

remove and rinse the wool thoroughly. If the black is not

sufficiently intense, make up a fresh ooze and repeat the process as

detailed. Perseverance will produce a satisfactory black.

A quicker method of producing a good and lasting black is by the

double-dye method, using Indigo and Walnut. This was the way favored

by William Morris, who toward the end of the last century did so

much to keep

61 |

|

| |

59 |

DYEING

handicrafts alive in England, when the industrial revolution

threatened their extinction.

Black with Indigo and Walnut.

Dye the wool first a deep blue, either by the Blue-pot or the

Hydrosulphite method. Rinse the blue yarn very throughly and then

transfer it to a dyebath containing a strong ooze already prepared

from walnut hulls, reinforced by a double handful of sumac berries.

In this dyebath boil the blue yarn for an hour or longer, then set

aside overnight to cool.

Next day take out the yarn, rinse well and examine in strong

daylight. If the color is a decided blue-black return to the walnut

dye-bath, add some more walnut hulls, and repeat boiling, with

addition of a pinch of copperas. Let the wool simmer for an hour or

so, then remove the dyepot from the fire and set aside to cool. When

it has become cold remove the yarn, rinse well and dry.

62 |

|

| |

60 |

Here in this little book we

have put down a few receipts for dyeing wool. From this small

beginning the real dyer can go forward and have a grand time

experimenting, and get his own palette of colors with which to work.

Some will last forever, and some will fade gradually; the deeper and

richer the shade the more permanent the color always.

Not everyone is a dyer; some have success and some do not, but

any one will have an interesting time. For the colors Blue and Rose,

Indigo and Madder are the best. But for the other colors the woods,

the flower-gardens are ours to experiment with. There is dye in

roots, barks, flowers, hulls, leaves, and lichens, and many of these

dyes have never been discovered, nor the mordants with which they

are made fast. The dyer who has a real love of color and much

patience can work all this out for himself. We hope this book will

just be a beginning, and that you will go ahead and find many more

lovely colors. Anyway we know that is what Miss Pettit would wish!

63 |

|

| |

61 |

[Back cover] |

|