|

HOME

DYEING WITH NATURAL DYES |

|

Page number |

I.D.#

pettit_

dye_

book_ |

Transcription |

Thumbnail |

| 001 |

Cover

|

UNITED STATES DEPARTMENT OF AGRICULTURE

Miscellaneous Publication No. 230

Washington, D. C.

December 1935

By MARGARET S. FURRY

Assistant Textile Chemist and

BESS M. VIEMONT

Assistant Textile Specialist

Division of Textiles and Clothing Bureau of Home

Economics |

|

| Inside front

cover |

Inside front

cover |

KEY TO COLORS AND DYE MATERIALS

| (For

wool only, unless otherwise specified) |

|

|

Black |

|

| Indigo

— walnut hulls1 _____ Logwood chips. __________ |

|

|

Blue |

|

| Indigo

(fermentation vat)1. Indigo (hydrosulphite vat)1 |

|

|

Brown and tan |

|

| Apple

bark |

|

| Birch

bark, yellow. |

|

| Birch

leaves, vellow |

|

|

Butternut hulls1. ________ |

|

|

Camomile flowers, yellow__ |

|

| Coffee

beans. _ Cotton flowers Cutch1,.. _ __ |

|

| Fustic

— madder |

|

|

Goldenrod flowers |

|

|

Goldenrod flowers — madder- _ Hemlock bark, western 1_____ |

|

|

Hickory bark, white |

|

|

Hickory nut hulls |

|

|

Hollygrape root |

|

|

Juniper berries |

|

|

Lichens |

|

| Maple

bark, Norway |

|

|

Marigold flowers J _ ________ |

|

|

Mountain-laurel leaves |

|

| Oak

bark, black or quercitron. Oak bark, chestnut _________ |

|

| Oak

bark, northern red *_____ |

|

| Oak

bark, white |

|

| Osage

orange or bois d'arc * |

|

| Pecan

hulls |

|

|

Persian berries 1____ __ ___._ |

|

| Poplar

leaves, Lombardy____ |

|

|

Sassafras root bark 1________ |

|

| Sumac

berries J__ ___________ |

|

| Tea

leaves, black |

|

| Tupelo

or black gum bark. __ Walnut bark, black- ________ |

|

| Walnut

hulls, black 1 ________ |

|

| Walnut

hulls, Persian or English i_______________-____ |

|

| Willow

bark, black _ _______ |

|

|

Gray: |

|

|

Butternut hulls 2__. ________ |

|

|

Chittambark2 ____ _______ |

|

| Indigo

— walnut hulls x _______ |

|

| Maple

bark, Norway 2_----_- |

|

| i

Both wool and cotton. a Cotton only. |

|

|

Gray—Continued. Page |

|

| Pecan

hulls 2 |

28 |

|

Sassafras root bark 2 |

29 |

| Sumac

berries 1 |

30 |

|

Green: |

|

|

Broomsedge-—indigo 1 |

34 |

|

Fustic—indigo J |

34 |

|

Goldenrod flowers—indigo |

34 |

|

Hickory bark, white—indigo x |

34 |

|

Persian berries—indigo |

34 |

|

Orange and buff: |

|

|

Broomsedge—madder |

35 |

|

Camomile flowers, yellow |

14 |

|

Coreopsis flowers |

17 |

| Dahlia

flowers |

18 |

|

Fustic—madder |

35 |

|

Hollygrape root- |

20 |

| Iron

buff 2 |

22 |

|

Lichens |

23 |

|

Madder1 |

25 |

| Onion

skins |

27 |

|

Quercitron—madder |

35 |

|

Purple: |

|

|

Cochineal |

15 |

|

Indigo—cochineal |

35 |

|

Red: |

|

|

Broomsedge—m adder |

35 |

|

Cochineal |

15 |

|

Goldenrod flowers—madder. |

35 |

|

Madder1 |

25 |

|

Quercitron—madder |

35 |

|

Yellow: |

|

| Apple

bark |

9 |

| Aster

flowers, Chinese |

8 |

|

Broomsedge * |

13 |

|

Camomile flowers, yellow |

14 |

| Chrome

yellow 2 |

15 |

| Cotton

flowers |

17 |

| Fustic

|

18 |

|

Goldenrod flowers |

19 |

|

Hickory bark, white 1 |

10 |

|

Lily-of-the-valley leaves |

24 |

|

Marigold flowers |

26 |

| Oak

bark, black or quercitron1. |

11 |

| Onion

skins |

27 |

| Osage

orange or bois d'arc |

27 |

|

Persian berries |

28 |

| Poplar

leaves, Lombardy |

29 |

| Privet

leaves |

29 |

|

Sunflower flowers |

31 |

| Tulip

tree leaves |

32 |

| Zinnia

flowers |

33 |

|

|

| |

|

KEY TO COLORS AND DYE MATERIALS

| (For

wool only, unless otherwise specified) |

|

| Black:

Page |

|

|

Indigo—walnut hulls1 |

34 |

|

Logwood chips |

24 |

|

Blue: |

|

| Indigo

(fermentation vat)1 |

20 |

| Indigo

(hydrosulphite vat)1 |

21 |

| Brown

and tan: |

|

| Apple

bark |

9 |

| Birch

bark, yellow |

10 |

| Birch

leaves, yellow |

13 |

|

Butternut hulls |

14 |

|

Camomile flowers, yellow |

14 |

|

Chittam bark |

10 |

| Coffee

beans |

16 |

| Cotton

flowers |

17 |

| Cutch1 |

18 |

| Fustic |

18 |

|

Fustic—madder. _ |

35 |

|

Goldenrod flowers |

19 |

|

Goldenrod flowers—madder |

35 |

|

Hemlock bark, western |

10 |

|

Hickory bark, white |

10 |

|

Hickory nut hulls |

19 |

|

Hollygrape root |

20 |

|

Juniper berries |

22 |

|

Lichens |

23 |

| Maple

bark, Norway |

11 |

|

Marigold flowers 1 |

26 |

|

Mountain-laurel leaves |

27 |

| Oak

bark, black or quercitron- |

11 |

| Oak

bark, chestnut |

12 |

| Oak

bark, northern red 1 |

12 |

| Oak

bark, white |

12 |

| Osage

orange or bois d'arc L. |

27 |

| Pecan

hulls |

28 |

|

Persian berries x |

28 |

| Poplar

leaves, Lombardy |

29 |

|

Sassafras root bark 1 |

29 |

| Sumac

berries J |

30 |

| Tea

leaves, black- |

31 |

| Tupelo

or black gum bark |

12 |

| Walnut

bark, black. |

12 |

| Walnut

hulls, black |

32 |

| Walnut

hulls, Persian or English |

32 |

| Willow

bark, black |

12 |

|

Gray: |

|

|

Butternut hulls 2 |

14 |

|

Chittam bark 2 |

10 |

|

Indigo—walnut hulls J |

34 |

| Maple

bark, Norway 2 |

11 |

| 1

Both wool and cotton. * Cotton only. |

|

|

Gray—Continued. Page |

|

| Pecan

hulls 2 |

28 |

|

Sassafras root bark 2 |

29 |

| Sumac

berries 1 |

30 |

|

Green: |

|

|

Broomsedge-—indigo 1 |

34 |

|

Fustic—indigo 1 |

34 |

|

Goldenrod flowers—indigo |

34 |

|

Hickory bark, white—indigo * |

34 |

|

Persian berries—indigo |

34 |

| Orange

and buff |

|

|

Broomsedge—madder |

35 |

|

Camomile flowers, yellow |

14 |

|

Coreopsis flowers |

17 |

| Dahlia

flowers |

18 |

|

Fustic—madder |

35 |

|

Hollygrape root |

20 |

| Iron

buff 2 |

22 |

|

Lichens |

23 |

|

Madder1 |

25 |

| Onion

skins |

27 |

|

Quercitron—madder |

35 |

|

Purple: |

|

|

Cochineal |

15 |

|

Indigo—cochineal |

35 |

|

Red: |

|

|

Broomsedge—madder |

35 |

|

Cochineals |

15 |

|

Goldenrod flowers—madder |

35 |

|

Madder1 |

25 |

|

Quercitron—madder |

35 |

|

Yellow: |

|

| Apple

bark |

9 |

| Aster

flowers, Chinese |

8 |

|

Broomsedge * |

13 |

|

Camomile flowers, yellow |

14 |

| Chrome

yellow 2 |

15 |

| Cotton

flowers * |

17 |

| Fustic

|

18 |

|

Goldenrod flowers |

19 |

|

Hickory bark, white 1 |

10 |

|

Lily-of-the-valley leaves |

24 |

|

Marigold flowers |

26 |

| Oak

bark, black or quercitron1 |

11 |

| Onion

skins |

27 |

|

Osage orange or bois d'arc |

27 |

|

Persian berries |

28 |

| Poplar

leaves, Lombardy |

29 |

| Privet

leaves |

29 |

|

Sunflower flowers |

31 |

| Tulip

tree leaves |

32 |

| Zinnia

flowers |

33 |

|

|

| |

1 |

UNITED STATED DEPARTMENT OF AGRICULTURE

MISCELLANEOUS PUBLICATION NO. 230

Washington, D. C.

December 1935

HOME DYEING WITH NATURAL DYES

By Margaret S.Furry, assistant textile chemist, and Bess M.

Viemont, assistant textile specialist, Division of Textiles and

Clothing, Bureau of Home Economics

CONTENTS

| |

Page |

|

Introduction |

1 |

|

Color fastness. |

2 |

|

Color combinations |

3 |

|

Equipment and supplies |

4 |

|

Steps in the dyeing process |

5 |

|

Weighing |

5 |

|

Steps in dyeing process—Continued. |

|

|

Washing |

5 |

|

Mordanting |

5 |

|

Using the dye recipes |

7 |

|

Top-dyeing |

33 |

INTRODUCTION

The present wide-spread interest in

handicraft work has brought to the Department of Agriculture a demand for

reliable information on the use of tree barks, nut hulls, and other

natural dyestuffs gathered locally. Though for most purposes the synthetic

dyes manufactured by commercial chemical processes are more satisfactory,

there are certain qualities about natural dyes that give them commercial

value in handicraft work, and many handicraft workers prefer to use them

on materials for hooked rugs, hand-woven scarfs, coverlets, and other

articles they make for sale. These handicraft industries have become a

source of family income in some rural communities. Such projects are also

being developed in connection with various Federal and State relief

activities.

This publication 1 reports the results of

tests on about 65 natural dye materials when used for dyeing cotton and

wool cloth. Most of the dyes studied are of vegetable origin. In fact the

terms "natural" and "vegetable" dyes are often used interchangeably though

a few, such as cochineal, are of animal origin and iron buff and some

others are developed from mineral pigments.

Samples of all the dyes studied in these

experiments were given standard tests for color fastness. Many were

discarded as unsatisfactory (p. 8), and only recipes are included for

those that produced attractive colors fast to both light and washing.

Since the common names of trees and plants differ so much from place to

place, the scientific names are given. The college of agriculture in any

State will give help in identifying plant materials. In each locality

there are many natural dye materials that by one dye method or another

will give satisfactory colors. This publication is intended merely

1. Acknowledgment is made to Edna H. Fawcett, assistant pathologist,

Bureau of Plant Industry, for helpful suggestions; to C. A. Heed,

associate pomologist, Bureau of Plant Industry, for furnishing plant

materials; to S. F. Blake, senior botanist, Bureau of Plant Industry,

for identifying plants; and to Marion A. Belknap and Mary A. Phillips of

the Bureau of Home Economics, for general laboratory assistance.

|

|

| 1 |

3 |

2 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICULTURE as a guide for

such work. A few States have mimeographed directions 2 for using

natural dyes.

COLOR FASTNESS

The fastness or permanence of a

dye is important, but no dye is absolutely fast under all conditions. It

may be fast to light, or to perspiration, or to washing, but not fast to

all three. Furthermore, a dye may be fast on one fiber and not on another;

or it may be fast when dyed by one method and not fast when dyed by

another. Of all the textile fibers, wool can be dyed most easily, and the

resulting colors change the least. It combines with practically all dyes,

probably forming a chemical union with them. Cotton does not combine with

dyes so well, and fast colors are produced on it only by complicated

processes.

The need for a particular kind

of fastness depends on the nature of the color change and the use to be

made of the dyed fabric. For example, a fabric dyed brown with tree bark

may darken on. exposure to light. If used in a hooked rug this color

change might be satisfactory but on the other hand, in window draperies it

would soon become objectionable.

To make sure that the recipes given on pages 8 to 35 produce colors

permanent enough to be useful for most purposes, the dyed fabrics were

tested for their fastness to light and to washing by the following

methods. The results are included in the dye recipes.

For the light test, samples of the dyed fabrics were cut and exposed

for 40 hours to the rays of a carbon arc lamp. Throughout the test period

half of each piece was shielded from the light while the rays of the lamp

shone directly on the other half. Then the two parts were compared and the

fastness to light rated as follows: Good—no appreciable change of color;

fair—appreciable but not objectionable change of color; poor—objectionable

change of color.

Though these light tests were run in a standard fading apparatus, the

same method can be followed at home by exposing samples to the sunlight.

Cut 2-inch square openings in each of two pieces of heavy cardboard,

fasten a piece of the dyed cloth to one with gummed paper and cover with

the other piece of cardboard so that the openings correspond. It is

important that the light come through the fabric. Then place this'1

sample in its frame out of doors in the direct sunlight and tilted towards

the sun. After a few days remove and compare the section exposed to the

sun with the covered portion.

For the washing test, samples were prepared by sewing a 2 by 4 inch

piece of dyed fabric to a similar piece of un-dyed material. On such a

sample the bleeding or staining of a dye, as well as fading, can be

determined. It was then placed in a half-pint fruit jar partly filled with

neutral soap solution (0.5 percent for wool and-0.1 percent for cotton) at

120° F. and agitated in a shaking machine for 30 minutes. The sample was

then removed, squeezed through, a wringer, and rinsed by agitating in

water for 10 minutes. Rinsing was repeated five times and the temperature

of each rinse gradually dropped to luke-

2 rocket, D. W., and pycha, R. C. home

spinning and weaving foe a vocation; dyes and dyeing. N. Mex. State Bd.

Vocat. Ed., Albuquerque. 201 pp., illus. 1933. [Mimeographed.]

Sageb, A. the use of natural dyes in home

ceafts. Oreg. State Col. Ext. Serv., Home Econ. 604,11 pp. 1934.

[Mimeographed.]

Sewell, B. H., and mobeow, M. vegetable

dyes bulletin. N. Mex. Dept. Vocat. Ed., Santa Fe. 8 pp., illus. 1934.

[Mimeographed, |

|

| 2 |

3 |

HOME DYEING WITH NATURAL DYES

warm. The samples were dried quickly, then compared with the original

unwashed fabric, and rated good, fair, and poor, as for the light test. A

similar test can easily be made at home.

COLOR COMBINATIONS

The craft dyer needs to know how to combine colors as well as how to

produce them. When harmoniously combined they add beauty and sales value

to handicraft articles. Therefore an understanding of a few of the

principles involved will aid the dyer in producing satisfactory colors and

color combinations.

Primary colors are yellow, blue, and red. All other colors are made

from them.

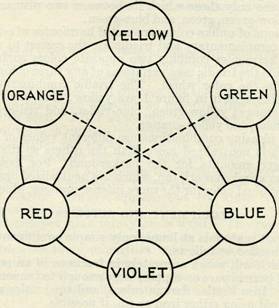

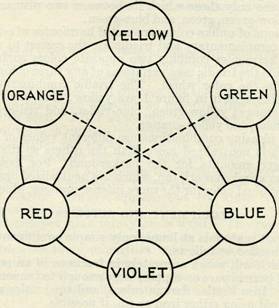

figure 1.—A color wheel showing the primary colors—yellow, blue,

red—and the secondary colors-green, violet, and orange.

Secondary colors—green, violet,

and orange—are made by combining two primaries. Yellow and blue give

green; blue and red produce violet; and red and yellow make orange.

Intermediate colors are formed

by combining a primary and a secondary color. Mixing yellow with green

produces yellow-green; blue with green a blue-green; red with blue a

red-violet; red with orange a red-orange; and yellow with orange a

yellow-orange.

Complementary colors are pairs

of opposites, as yellow and violet or red and green. Opposite

intermediates are also complementary

(%. 1).

The three properties which

describe a color are hue, value, and intensity. Hue is the name of the

color such as yellow or green. Value means the depth or the lightness or

darkness of a color as measured in terms of white or black. Light values,

or those approaching white, are called tints, while dark ones or those

approaching black |

|

| |

4 |

4 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICULTURE are called shades. In

dyeing, tints can be made by using less dye material in proportion to the

weight of cloth. Shades are made either by increasing the relative amount

of dye material or by adding black. Intensity means the brightness of a

hue or the amount of a pure color it contains. The intensity of any color

is softened or subdued by mixing with varying amounts of its complement or

the color opposite it in the color wheel (fig. 1).

Certain rules govern the combining of

colors. Similar hues may be used together in self-tone and neighboring

color harmonies—sometimes called harmonies of likeness. Self-tone

harmonies consist of tints and shades of one color such as orange, tan,

and brown. Neighboring color harmonies combine colors that are side by

side in the color wheel (fig. 1). However, when combining neighboring

colors it is best to use only those which lie between two primary hues,

for example, yellow-green, green, and blue-green.

Combinations of unlike colors are called

harmonies of contrast, and of these the complementary and triadic are the

easiest to use. Complementary harmonies combine two opposite colors such

as orange and blue, while the triadic uses variations of any three colors

which are equidistant in the color wheel. The triadic combinations

possible from the colors shown in figure 1 are yellow, blue, and red;

green, violet, and orange; yellow-green, blue-violet, and red-orange;

blue-green, red-violet, and yellow-orange.

The most pleasing combinations use

different values of soft colors, one of which is neutralized more than the

others so that it can be used in larger amounts for the background. For

example, in a hooked rug or a woven scarf, tan, which is a neutralized

orange, makes a good background color for the more intense oranges, blues,

or greens in the design.

EQUIPMENT AND SUPPLIES

To dye craft materials at home, only

simple equipment and a few supplies are needed, as follows:

Scales, which will weigh accurately in

fractions of an ounce.

Kettles of enamelware or copper, large

enough to immerse the cloth completely. Iron kettles darken colors, and

tin kettles make colors harsh, so avoid using either iron or tin, if

possible.

Large pails or tubs, in which to rinse

the dyed fabrics.

Gallon, peck, and quart measures,

tablespoons, and dippers.

Cheesecloth or coarse muslin, for

straining the dye liquor.

Sticks of smooth wood or glass towel

rods for stirring and turning the material in the dye bath.

A good stove. If possible, have it set

lower than usual so that lifting the water and stirring the goods in the

dye bath will be easier.

A thermometer to test the temperature

of the dye bath and rinse waters.

Rubber gloves to protect the hands from

dyes.

A clothesline stretched in the shade.

Soft water, such as filtered rain

water. Have plenty of water to cover the fabric while dyeing, also

plenty for rinsing.

Chemicals and dye materials can be obtained from drugstores and

botanical-drug supply houses.

|

|

| |

5 |

STEPS IN THE DYEING PROCESS

WEIGHING

The weight of the material to be dyed

determines the quantity of soap to use in washing it before dyeing, as

well as the quantity of chemicals and dyestufts to use in the mordanting

and dyeing processes. Therefore the first step is to weigh the yarn or

fabric while it is still dry.

WASHING

In order that the dye solution may

penetrate thoroughly and evenly, the yarn or fabric should be washed in

soap and water and should be well rinsed. Any starch and sizing materials

will prevent the fibers from wetting out readily and must be removed.

Spots and stains may also cause uneven dyeing, and should be treated

before washing.3

WOOL

Make a suds of good neutral soap in

lukewarm soft water, using for each pound of wool yarn or fabric about

three-fourths of an ounce of soap to 5 gallons of lukewarm water (95° F.).

Wash the material thoroughly for 30 minutes, and squeeze out the suds.

Then wash it a second time in lukewarm suds for 30 minutes, this time

using one-fourth as much soap. After squeezing out the suds, rinse it 3 or

4 times, 10 minutes each time, in lukewarm water.

To prevent felting and shrinking, handle

wool quickly and pass it directly from the suds to the rinses without

delay. Also have the temperature of the suds and rinses the same and never

more than lukewarm. Sudden changes in temperature cause wool to shrink and

become harsh. Always squeeze out the rinse water evenly. Never wring or

twist wool.

Often wool not yet spun into yarn is

dyed. The raw wool must first be thoroughly scoured and cleaned to remove

the natural wax and grease because these impurities tend to make the fiber

water-repellent and the dye cannot penetrate it. After being scoured and

dyed, the wool is carded and spun into yarn. Different colors may be

carded together to make interesting color combinations.

COTTON

Make a suds of good neutral soap in hot,

soft water, using for each pound of cotton material about three-fourths of

an ounce of soap in 5 gallons of hot water (140° F.). Wash thoroughly for

30 minutes, wring out the suds, and wash in a second suds, using half as

much soap for a pound of material. Rinse once in hot water. For the second

rinse have the water still hotter and let the cotton soak a half hour or

more. Then follow with 2 or 3 cooler rinses.

MORDANTING

Many of the natural dyes will fade and

"bleed" badly unless the yarn or fabric is first treated with a chemical

called a mordant, which helps to fix the color to the fiber. The mordants

commonly used

3. United States Department of

Agriculture, Bureau of Home Economics. Stain removal from fabrics; home

methods. U. S. Dept. Agr. Farmers' Bull. 1474, 30pp., illus. 1926.

' |

|

| |

6 |

6 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICULTURE with the

natural dyestuffs are alum, chrome (potassium dichromate), copperas

(ferrous sulphate), and tannic acid or some other source of tannin such as

oak galls or sumac leaves. Commercial dyers use oils and other substances

too difficult for the home dyer to apply.

By using different mordants, a variety of shades and sometimes even

different colors may be obtained from one dye. For example, on wool,

dahlia flowers used with a chrome mordant give an orange color and with

alum a light yellow. Cochineal mordanted with alum gives a red and with

chrome a purple.

Both wool and silk have the property of holding chemicals in their

fibers. For example, when wool is boiled in a solution of potassium

dichromate (chrome mordant) a certain amount of chromium oxide is held in

the fiber, and the dyestuff then combines with this mordanted wool to form

a permanent color.

Cotton and the other vegetable fibers do not absorb the metallic

mordants so readily as wool. However, they combine well with tannic acid,

which is used either as a mordant itself or as an agent for fixing

metallic mordants in the fibers.

METHODS FOR MORDANTING WOOL

Alum.—For each pound of dry wool, use:

4 ounces potash alum. 1 ounce cream of tartar.

Dissolve the alum and cream of

tartar in 4 to 4K gallons of cold, soft water and immerse the wool yarn or

cloth after it has been thoroughly wet and squeezed out of water. Heat

gradually to boiling, stirring and turning the wool all the time. Boil

gently for 1 hour. As the water boils away, add more so that the

proportion of liquid to wool remains the same. Cool and allow the wool to

stand overnight in the mordant. In the morning squeeze it from this bath,

roll in a dry towel, and put in a cool place. Rinse the mordanted material

well just before putting it into the dye bath.

Chrome.—For each pound of dry

wool, use:

Yz

ounce potassium dichromate.

Dissolve the potassium dichromate in 4 to 4% gallons of cold, soft

water and follow the directions for mordanting wool with alum.

METHODS FOR MORDANTING COTTON

Alum.—For each pound of dry cotton, use:

4 ounces potash alum.

1 ounce sodium carbonate (washing

soda).

Dissolve the alum and washing soda in 4

to 4 1/2 gallons of cold, soft water and immerse the cotton after it has

been thoroughly wet and wrung out of water. Stir well, heat gradually, and

boil for 1 hour. Cool and let stand in the bath overnight. In the morning

squeeze the cotton from the mordant bath, roll in a dry towel, and put in

a cool place. Rinse the mordanted material well just before putting it

into the dye bath.

Alum-tannin-alum.—For each pound of dry

cotton, use:

8 ounces potash alum.

2 ounces sodium carbonate (washing

soda).

10 ounces powdered oak galls, or 1

ounce tannic acid, or extract from 4 to 6 ounces dry sumac leaves.

|

|

| |

7 |

HOME DYEING WITH NATURAL DYES 7

Dissolve half of the alum and half of the washing soda in 4 to 4 1/2

gallons of cold, solt water and immerse the cotton after it has been

thoroughly wet and wrung out of water. Stir well, heat gradually to

boiling, and boil for 1 hour. Cool and allow the material to stand

overnight in the mordant. In the morning squeeze the material out, rinse,

and put into a bath of oak galls, or tannic acid, or sumac leaves at 140°

to 160° F. Work it in this bath for 1 hour and let stand overnight. Then

rinse slightly. With the rest of the alum and washing soda prepare another

bath in 4 to 4 1/2 gallons of water, and mordant the material again in

alum. Let stand overnight in the mordant bath. In the morning squeeze out

the cotton and rinse just before dyeing.

To prepare the extract of sumac leaves, soak the dry leaves for

one-half hour, then boil 30 minutes, strain, and let the bath cool to the

proper temperature.

USING THE DYE RECIPES

The dye recipes are arranged alphabetically by the name of the flower,

bark, or other dye material. To avoid repetition in the recipes, under the

heading Barks are grouped the four methods of dyeing with bark, followed

by special information about each kind.

In order to get good results from the dye recipes, the following

general points should be clearly understood:

All the recipes are based on 1 pound of wool or cotton weighed while

dry before it is mordanted.

The dye materials must be weighed or measured, prepared as the dye

recipe directs, and strained into the water for the dye bath.

Use plenty of water (filtered rain water), at least 4 to 4% gallons for

each pound of yarn or cloth. Otherwise the material will be crowded and

will come out streaked or spotted.

Rinse the mordanted yarn or fabric well, squeeze lightly, then quickly

immerse it in the dye bath. Stir and turn it so that all parts are heated

evenly. Be sure to keep the goods well opened oat and in constant motion.

The temperature of the dye bath must be just lukewarm when wool is put

in, but for cotton it can be warmer. Then heat gradually and simmer or

boil according to the directions.

As the dye bath boils down, lift out the yarn or cloth and add boiling

water from time to time. The quantity of dye bath should be kept the same

throughout the process.

Rinse the dyed yarn or fabric first in water of the same temperature as

the dye bath and finally in cooler water. Keep rinsing, using plenty of

water until the rinse water is clear. Crocking or rubbing of the dye from

the material is usually caused by insufficient rinsing.

Squeeze or press out as much water from the dyed material as possible.

Do not twist or wring it, for this causes streaks and wrinkles that are

difficult to remove.

Roll the material for a few minutes in a clean cloth or towel to absorb

any excess moisture; then shake it well and hang in the shade.

|

|

| |

8 |

8 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICITLTTJKE When the fabric

is dry enough to iron, cover it with a cloth and press on the wrong side.

Dye the amount of yarn or cloth of each

color needed for a piece of handicraft work at one time, instead of trying

to match the color by a second dyeing. Vegetable dye materials vary so

much that it is almost impossible to duplicate colors exactly.

To obtain colors lighter or darker than

those suggested by the recipes, decrease or increase the given quantities

of dyestuffs.

Many craft workers find it easier and

pleasanter to dye their materials out of doors.

The following plant materials, sometimes

suggested for dyeing, do not produce fast colors on wool or cotton and

therefore are not included in the dye recipes: Annatto seeds, Japanese

barberry root, beets, crab-apple peelings, the fruit of the blackberry,

blueberry, cranberry, and pokeweed, purple iris flowers, mosses, peach

leaves, red roses, sumac leaves, turmeric, and willow leaves.

aster flowers, chinese (Collistemma chinense)

The color principles, caliistephin and

asterin, are found in asters, especially the deep purple-red flowers. The

asters used in testing this recipe were rose-pink. On chrome mordanted

wool they gave a light greenish yellow which has good color fastness.

Light greenish yellow.—For each pound of

wool mordanted with chrome, use:

Yz bushel fresh aster flowers.

Mordant the wool with chrome (p. 6). Cut

the flowers into small pieces, boil for 10 minutes in water to cover,

strain, and add enough water for the dye bath (4 to 4K gallons). Immerse

the wool, thoroughly rinsed and squeezed out of water, boil for 20

minutes, then rinse and dry.

BARKS

The barks of many common trees supply

coloring materials for yarns and cloth. Of the barks discussed here,

black, or quercitron, oak has the greatest coloring power. Barks produce

colors on wool varying from light tan to brown, but on cotton only the

lighter shades are obtained. In addition to those reported (pp. 9 to 13)

white ash bark, madrone, silver maple, willow oak, and sweetgam bark were

also tested, but they are omitted from this publication because their

colors are very similar to those of other barks.

Most barks are best collected in the fall

or winter, though the resinous kinds may be gathered in the spring.

Generally the inner bark is used and it may be either fresh or dried, but

usually fresh ones give a stronger dye. They must be carefully dried and

stored where they will not become damp and moldy.

The coloring principles of these dyes are

closely combined with tannin. Because of this tannin fabrics dyed with

bark extracts are often not fast to light but soon darken and become

brown. To prevent this change the yarn or fabric after it is dyed can be

treated with certain chemicals such as potassium dichromate, ferrous

sulphate, and copper sulphate. These tend to fix or remove the excess

tannin. Dye methods 2, 3, and 4 (p. 9) use this process. |

|

| |

9 |

9 Dye

method 1.—For each pound of wool yarn or cloth not mordanted or mordanted

with alum or with chrome, or for each pound of cotton yarn or cloth

mordanted with alum or with alum-tannin-alum., use:

1 peck finely chopped bark.

Mordant the wool (p. 6) or cotton (p. 6).

Soak the bark overnight in 2 to 2% gallons of soft water. In the morning

heat slowly and boil for 2 hours, adding hot water to replace what boils

away. Strain twice through cheesecloth and to this dye extract add enough

cold water to make 4 to 4^ gallons for the dye bath. Let it cool until

lukewarm, then immerse the material, which has been thoroughly rinsed and

squeezed out of water, and boil for 30 minutes. Rinse and dry.

Dye method 2.—For each pound of wool yarn

or cloth mordanted with alum, or for each pound of cotton yarn or cloth

mordanted with alum or with alum-tannin-alum, use:

1 peck finely chopped bark.

% ounce potassium dichromate.

Y& ounce acetic acid, or 6 to 7

tablespoons vinegar.

Mordant the wool with alum (p. 6) or the

cotton with alum or alum-tannin-alum (p. 6). Soak the bark overnight in 2

to 2% gallons of soft water. In the morning heat slowly and boil for 2

hours, adding hot water to replace what boils away. Strain twice through

cheesecloth and to this dye extract add enough cold water to make 4 to 4%

gallons for the dye bath. Let it cool until lukewarm, then immerse the

material, which has been thoroughly rinsed and squeezed out of watej, and

boil for 30 minutes. Without rinsing, put the yarn or cloth into a boiling

bath of the potassium dichromate and acetic acid in 4 gallons of soft

water, stir carefully, and boil for 10 minutes. Rinse and dry.

Dye method 3.—For each pound of wool yarn

or cloth mordanted with alum or with chrome, use:

1 peck finely chopped bark.

1/2 ounce copper sulphate (blue

vitriol).

1/2 ounce acetic acid, or 6 to 7

tablespoons vinegar.

Mordant the wool (p. 6) and dye as

directed in dye method 2, using copper sulphate in place of potassium

dichromate.

Dye method 4.—For each pound of wool yarn

or cloth mordanted with alum, use:

1 peck finely chopped bark.

Ye ounce ferrous sulphate (copperas).

Mordant the wool (p. 6) and dye as

directed in dye method 2, using ferrous sulphate in place of potassium

dichromate and acetic acid or vinegar.

apple bark (Mains sylvestris)

On wool, apple bark gives a dark

yellow-tan and a brass color with fair fastness to light and good fastness

to washing.

Dark yellow-tan.—Wool: Alum mordant (p.

6); dye method 1 or 4 (p. 9).

Brass.—Wool: Chrome mordant (p. 6); dye

method 1 (p. 9).

10626°—35———2

|

|

| |

10 |

10 MISC. PUBLICATION 230, U. S.

DEPT. OF AGRICULTURE BIRCH BARK, YELLOW (Betula lutea)

The bark used in these recipes was yellow birch, common in the

Northeastern States. By one method of dyeing it gave on wool a dark

yellow-tan which has fair fastness to light and good fastness to washing;

by another it gave a yellow-brown which has good color fastness.

Dark yellow-tan.—Wool: Alum mordant (p. 6); dye method 3

(p. 9).

Yellow-brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

chittam bark (Rhamnus purshiana)

Chittam bark is extensively collected in Oregon and Washington States

in manufacturing the drug cascara sagrada. The bark also yields a dye that

colors wool a dark yellow-tan, which has fair color fastness, and a light

brown that has good fastness. On cotton, chittam bark gives a good fast

tan and a gray with fair color fastness. Use one-fourth of a peck of

chittam bark to 1 pound of wool or cotton.

Dark yellow-tan.—Wool: Chrome mordant (p. 6); dye method 1 (p. 9).

Light brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

Tan.—Cotton: Alum-tannin-alum mordant (p. 6); dye method 2 (p. 9).

Gray.—Cotton: Alum-tannin-alum mordant (p. 6); dye method 4 (p. 9).

hemlock bark, western (Tsuga heterophyllo)

Hemlock bark is commonly used as a dye and tanning material. The

species used in these recipes was western hemlock, which grows in hilly

and rocky wooded areas of the western part of the United States. The

eastern hemlock (Tsuga canadensis), commonly called spruce pine, is

also used in dyeing.

On wool, hemlock bark produces dark shades of yellow-tan and rose-tan,

both with fair color fastness. On cotton, hemlock bark gives a rose-tan

that has fair fastness to light and good fastness to washing.

Dark yellow-tan.—Wool: Chrome mordant (p. 6); dye method 2 (p. 9).

Dark rose-tan.—Wool: Alum mordant (p. 6); dye method 2 (p 9). Cotton:

Alum-tannin-alum mordant (p. 6); dye method 1 or 2 (p. 9).

HICKORY BARK, WHITE (Hicorid alba)

The bark used in this test was

the white hickory or mockernut, which grows throughout the eastern half of

the United States. On wool, it gives a brass color and a dark yellow-tan

which have fair fastness to light and good fastness to washing; also a

yellow-brown which has good color fastness. On cotton, this bark gives a

gold and a brass color, with good fastness.

Gold.—Cotton: Alum-tannm-alum

mordant (p. 6); dye method 1 (p. 9).

Brass.—Wool: Chrome mordant (p.

6); dye method 1 (p. 9). Cotton: Alum-tannin-alum mordant (p. 6); dye

method 2 (p. 9).

Dark yellow-tan.—Wool: Alum

mordant (p. 6); dye method 3 (p. 9).

Yellow-brown.—Wool: Alum mordant

(p. 6); dye method 2 (p. 9) |

|

| |

11 |

HOME DYEING WITH NATURAL DYES 11

maple bark, Norway (Acer platanoides).

By one method of dyeing on wool, Norway maple bark produces a rose-tan;

by another method, a light brown. Both have fair fastness to light and

good fastness to washing. On cotton, this bark gives a light gray which

has fair fastness to light and good fastness to washing; and a drab, which

has good color fastness. The bark of the silver maple, which grows

throughout eastern North America, produces similar colors on wool and

cotton.

Rose-tan. — Wool: Alum mordant (p. 6); dye method 3 (p. 9). Wool:

Chrome mordant (p. 6); dye method 1 (p. 9). . Light brown. — Wool: Alum

mordant (p. 6); dye method 2 (p. 9).

Light gray. — Cotton: Alum- tannin-alum mordant (p. 6); dye method 1

(p. 9).

Drab. — Cotton: Alum-tannin-alum mordant (p. 6); dye method 2 (p. 9).

OAK BARK, BLACK OR QUERCITRON (QuerCUS

Quercitron is the dyestuff prepared from the inner bark of black or

quercitron oak trees, found in the eastern half of the United States,

especially in Pennsylvania, Georgia, and the Carplinas. The bark itself

may be used, or a pure dye extract of quercitron may be purchased. The

extract has much greater coloring power than the bark. The following

directions are for the use of the quercitron extract. If the bark is used

instead of the extract, follow dye method 1, chrome mordant (p. 9), or

method 2 (p. 9). Since tannin dulls the brilliancy of colors, prolonged

boiling in a quercitron dye bath must be avoided.

On wool, quercitron produces a gold color with good fastness to light

and to washing, and a yellow-tan that has fair fastness to light and good

fastness to washing. On cotton, quercitron gives a gold color which has

good color fastness.

Gold. — Method 1 : For each pound of wool mordanted with chrome, use:

% ounce quercitron extract.

Mordant the wool with chrome (p. 6). Dissolve the quercitron extract in

enough soft water for the dye bath (4 to 4% gallons), immerse the

yarn or cloth thoroughly rinsed and squeezed out of water, and boil for 30

minutes. Rinse and dry.

Method 2: For each pound of cotton mordanted with alum-tannin-alum,

use:

Yz ounce quercitron extract.

Ye ounce potassium dichromate.

yg ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the cotton in alum-tannin-alum according to directions on page

6. Dissolve the quercitron in 4 to 4% gallons soft water for the dye bath,

immerse the goods, thoroughly rinsed and squeezed out of water, and boil

for 30 minutes. Without rinsing, put the material into a boiling bath of

the potassium dichromate and acetic acid. Stir carefully, and boil for 10

minutes. Rinse and dry.

Yellow-tan. — For each pound of wool mordanted in alum, use:

Yz ounce quercitron extract.

% ounce potassium dichromate.

Ys ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool in alum (p. 6) and dye as for Gold, method 2.

|

|

| |

12 |

12 MISC. PUBLICATION 230, U. S. DEPT. OF AGRICULTURE

oak bark, chestnut (Quercus montana)

The chestnut oak is native to the eastern part of the United States

from Maine to Alabama. On wool, chestnut-oak bark produces a dark

yellow-tan which has fair fastness to light and good fastness to washing,

and a light brown which has good color fastness.

Yellow-tan.—Wool: Chrome mordant (p. 6); dye method 1 (p. 9).

Light brown.—Wool: Alum mordant (p. 6); dye method 2, or 3

(p. 9).

oak bakk, northern red (Quercus borealis maxima)

Northern red oak trees are found throughout the eastern half of the

United States. On wool, this bark gives a rose-tan which has fair color

fastness; also a tan, a yellow-tan, and a light brown, which have good

color fastness. On cotton, a rose-tan is obtained with fair fastness to

light and good fastness to washing.

Tan.—Wool: Chrome mordant (p. 6); dye method 3 (p. 9).

Rose-tan.—Wool: No mordant; dye method 1 (p. 9). Cotton: Alum mordant

(p. 6); dye method 2 (p. 9).

Yellow-tan.—Wool: Chrome mordant (p. 6); dye method 1 (p. 9).

Light brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

oak bark, white (Quercus alba)

The bark of the white oak, which grows in the eastern half of the

United States, produces on wool a dark yellow-tan, a light brown, and a

khaki color. The color fastness is good.

Dark yellow-tan.—Wool: Alum mordant (p. 6); dye method 1, 3, or 4 (p.

9).

Light brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

Khaki.—Wool: Chrome mordant (p. 6); dye method 1 (p. 9).

TUPELO OR BLACK GUM BARK (NySSO, Sytvatica)

The bark of the tupelo, or black gum, common in the eastern half of the

United States, produces on wool a dark yellow-tan and a khaki color. Both

colors have fair fastness to light and good fastness to washing.

Dark yellow-tan.—Wool: Alum mordant (p. 6); dye method 1 or 3 (p. 9).

Khaki.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

walnut bark, black (Juglans nigra)

On wool, black walnut bark gives a khaki color which has fair fastness

to light and good fastness to washing. A yellow-brown and a dark brown

also are obtained, which have good color fastness.

Khaki.—Wool: Chrome mordant (p. 6); dye method 1 (p. 9).

Yellow-brown.—Wool: Alum mordant (p. 6); dye method 3 (p. 9).

Dark brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

willow bark, black (Salix nigra)

The black willow tree is native to the eastern part of North America.

On wool, black willow bark produces a rose-tan and a light brown. Both

have fair fastness to light and good fastness to washing.

|

|

| |

13 |

HOME DYEING WITH NATURAL DYES 13

Rose-tan.—Wool: Alum mordant (p. 6); dye method 1 or 3 (p. 9). Light

brown.—Wool: Alum mordant (p. 6); dye method 2 (p. 9).

BIRCH LEAVES, YELLOW (Betuld lutea)

Yellow birch is one of the most valuable forest trees of the Northern

States. On wool, its leaves produce a yellow-tan that has fair fastness to

light and good fastness to washing. The leaves can be used either fresh or

dry; if the leaves are fresh, use twice the quantity stated below.

Yellow-tan.—For each pound of wool mordanted with alum, allow:

% peck dry birch leaves.

Mordant the wool with ahim (p. 6). Soak the leaves overnight in enough

water to cover. In the morning boil for 1 hour, strain, and add water to

make 4 to 4% gallons for the dye bath. Immerse the wool material

thoroughly rinsed and squeezed out of water and boil for 30 minutes. Rinse

and dry.

broomsedge (Andropogon virginicus)

Broomsedge or "dyer's broom" grows on open waste ground from

Massachusetts to Illinois and south to Florida and Texas. The entire stalk

and leaves are used for dyeing. Gathered at any time of year it will color

but the dye is stronger in the summer when the plant is green. It can be

cut in June and July, dried, and used as needed.

On wool, broomsedge gives a light greenish yellow and a brass color;

and on cotton, a yellow and a gold. All have good color fastness except

the yellow and it has fair fastness to light. Broomsedge can be used with

indigo to give shades of green and with madder to give henna and a brick

color.

Light greenish yellow.—For each pound of wool mordanted with alum, use:

% peck dry broomsedge.

Y& ounce copper sulphate.

% ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p. 6). Cut up the dry broomsedge, steep in

water to cover, and boil for 20 minutes. Strain and add enough cold water

to make 4 to 4}£ gallons for the dye bath. Immerse the yarn or cloth

thoroughly rinsed and squeezed out of water and boil for 20 minutes.

Without rinsing put in a boiling bath of the copper sulphate and acetic

acid in 4 gallons of water, stir carefully, and boil for 10 minutes. Rinse

and dry.

Brass.—For each pound of wool mordanted with chrome, use:

% peck dry broomsedge.

Mordant the wool with chrome (p. 6). Cut up the dry broom-sedge, steep

in water to cover, and boil for 20 minutes. Strain and add enough cold

water to make 4 to 4% gallons for the dye bath. Immerse the yarn or cloth

thoroughly rinsed and squeezed out of water and boil 20 minutes. Rinse and

dry.

Yellow.—For each pound of dry cotton mordanted with alum-tannin alum,

allow:

% peck dry broomsedge.

|

|

| |

14 |

14 MISC. PUBLICATION 230, U. S. DEPT.

OF AGRICULTURE Mordant the

cotton with alum-tannin-alum (p. 6) and dye as directed under Brass.

Gold.—For each pound of cotton mordanted in alum-tannin-alum, allow:

% peck dry broomsedge.

% ounce potassium dichromate.

% ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the cotton with alum-tannin-alum (p. 6), and dye as for Light

Greenish Yellow.

buttekntjt hulls (Juglans cinereo)

The bark, root, leaf, and hull of the butternut tree which is found in

the woods of the Eastern and Central States, are all used for dyeing. The

mature nuts are gathered when still green and allowed to ripen partly. The

hulls are then ready for use or they may be dried and used as needed.

On wool, mordanted with alum, butternut hulls produce a fast brown. If

ferrous sulphate is added, the color becomes darker, even to black,

depending on the amount used. The light fastness is fair. On cotton,

butternut hulls give a greenish tan, which has fair color fastness and a

gray that has good fastness.

Brown.—For each pound of wool mordanted with alum, allow: 1 peck green

butternut hulls.

Mordant the wool with alum (p. 6). Soak the hulls in water to cover for

30 minutes, then boil 15 to 30 minutes, strain, and add enough cold water

to make 4 to 4K gallons for the dye bath. Immerse the yarn or cloth

thoroughly rinsed and squeezed out of water, and boil for 30 minutes.

Rinse and dry.

A darker brown is obtained if the dyed material is put, without

rinsing, into a boiling bath containing one-sixth of an ounce of ferrous

sulphate (copperas) in 4 to 4% gallons soft water. Boil for 10 minutes

longer; rinse and dry.

Greenish tan.—For each pound of cotton mordanted with alum, allow:

1 peck green butternut hulls.

Mordant the yarn or cloth with alum (p. 6) and proceed as for

Brown.

Gray.—For each pound of cotton mordanted with alum, allow:

1 peck green butternut hulls.

% ounce ferrous sulphate (copperas).

Mordant the cotton yarn or cloth with alum (p. 6) and dye as directed

under Brown. Without rinsing, put the yarn or cloth in a boiling bath of

the ferrous sulphate, stir carefully, and boil 10 to 15 minutes. Rinse and

dry.

camomile flowers, yellow (Anthemis tinctoria)

Yellow camomile flowers, or golden marguerites as they are sometimes

called, are becoming frequent in fields and waste places of this country.

The flowers come late in the summer and either fresh or dried may be used

for dyeing.

|

|

| 15 |

15 |

On wool mordanted with alum,

camomile flowers give a buff color which on washing in soapsuds becomes

brighter. It has fair color fastness. By other methods of dyeing, gold and

khaki colors of good fastness to light and to washing are obtained.

Camomile flowers do pot dye cotton. Buff.—For each pound of wool

mordanted with alum, allow:

7 quarts dry, crushed camomile flowers.

Mordant the wool with alum (p. 6). Boil the dry, crushed flowers in

water to cover for 25 minutes or until the color is gone, then strain, and

add enough cold water to make 4 to 4% gallons for the dye bath. Immerse

the yarn or cloth, thoroughly rinsed and squeezed out of water, heat

slowly, and boil for 30 minutes. Rinse and dry.

Gold.—For each pound of wool mordanted with chrome, allow: 7 quarts

dry, crushed camomile flowers.

Mordant the wool with chrome according to directions on page 6, and dye

as directed for Buff.

Khaki.—For each pound of wool mordanted with alum, allow:

7 quarts dry, crushed camomile flowers.

% ounce potassium dichromate.

% ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p. 6) and dye as for Buff. Then without

rinsing, put the wool into a boiling bath of the potassium dichromate and

acetic acid in 4 gallons of water, stir carefully, and boil for 10

minutes. Rinse and dry.

CHROME YELLOW

On cotton, without a mordant, lead acetate and potassium dichromate

produce a bright yellow with good color fastness. On wool, the color

fastness is poor.

Yellow.—For each pound of unmordanted cotton yarn or cloth, allow:

3 ounces lead acetate.

1 ounce potassium dichromate.

Dissolve the lead acetate and potassium dichromate separately in 4 to

4K gallons soft water for each. Dip the cotton, thoroughly wet and wrung

out of water, in lead acetate and then in the potassium dichromate. Stir

well, repeat four times; rinse, and dry.

COCHINEAL (COCCUS Cacti)

Cochineal is prepared from a dried insect, Coccus cacti, found

in Mexico and Central America. It can be obtained from many drug- and

dye-supply houses.

On wool, cochineal produces colors that have good fastness to light.

Most of them are also fast to washing, but some become slightly bluer

though they do not run or bleed. The colors American beauty red and purple

have good fastness to washing as well as good fastness to light. Cochineal

is not a satisfactory dye for cotton.

Rose-pink.—For each pound of dry wool, allow:

1 ounce powdered cochineal. 4 ounces oxalic acid. 4 ounces stannous

chloride. 1 ounce cream of tartar.

|

|

| |

16 |

16 MISC. PUBLICATION 230, U. S. DEFT. OF

AGRICULTURE Soak the cochineal

overnight in a little water. In the morning, add the oxalic acid, stannous

chloride, and cream of tartar, and boil for 10 minutes. Then add enough

cold water to make 4 to 4K gallons for the dye bath, immerse the wool,

thoroughly wet and squeezed out of water, and bring slowly to the boil

(about three-fourths of an hour). Boil for 1 hour, rinse, and dry.

If 2 ounces of cochineal are used in

place of the four-fifths of an ounce a light scarlet is obtained.

Flag red.—For each pound of dry wool,

allow:

3 1/2j ounces powdered cochineal.

3 1/2 ounces cream of tartar.

1 1/2 ounces concentrated nitric acid.

1/2 ounce stannous chloride.

Soak the cochineal and cream of tartar in

water, and add to the boiling water for the dye bath (4 to 4% gallons).

Boil for 10 minutes, then strain, and add the nitric acid and stannous

chloride previously dissolved in 1 cup of water.

(Caution: Always pour acid into water; never water into acid.)

Put in the dry wool, stir well, and

let boil for \% hours. Stir constantly. Rinse and dry.

American beauty red.—For each pound of

wool mordanted with alum, allow:

1 ounce powdered cochineal.

Mordant the wool with alum (p. 6). Soak

the cochineal in water for 1 hour, boil for 15 minutes, strain, and add

enough cold water to make 4 to 4K gallons for the dye bath. Immerse the

wool, thoroughly rinsed and squeezed out of water, heat gradually, and

boil for 1 % hours. Rinse and dry.

Purple.—For each pound of wool mordanted

with chrome, allow:

ly-z ounces powdered cochineal. 1

teaspoon vinegar.

Mordant the wool with chrome (p. 6). Boil

the cochineal and vinegar in a little water for 10 minutes and strain. Add

enough cold water to make 4 to 4}£ gallons for the dye bath, immerse the

mordanted wool, thoroughly rinsed and squeezed out of water, boil for 1 %

hours, rinse and dry.

coffee beans (Coffea arobica)

Coffee will dye wool a dark yellow-tan

that has good color fastness and a light brown that has fair fastness. The

colors on cotton are not fast.

Dark yellow-tan.—For each pound of wool

mordanted with chrome, allow:

1% pounds ground coffee.

Mordant the wool with chrome (p. 6). Boil

the coffee in water for 20 minutes, strain, and add enough cold water to

make 4 to 4K gallons for the dye bath. Immerse the yarn or cloth

thoroughly rinsed and squeezed out of water and boil for 30 minutes. Rinse

and dry.

Light brown.—For each pound of wool

mordanted with alum, allow:

1% pounds ground coffee.

% ounce ferrous sulphate (copperas).

Mordant the wool with alum (p. 6), and

dye as directed for Dark Yellow-Tan. Without rinsing put the wool into a

boiling bath of

|

|

| |

17 |

HOME DYEING WITH NATURAL DYES 17

ferrous sulphate in 4 gallons of water, stir carefully, and boil for 10

minutes. Rinse and dry.

cokbopsis floweks (Coreopsis sp.)

The coreopsis, commonly called the "yellow dye flower", is widely used

in coloring yarns and fabrics for handicraft purposes. On wool, the

flowers produce 'a dark burnt orange or terra cotta, which has good color

fastness. Coreopsis flowers do not dye cotton.

Dark burnt orange.—For each pound of wool mordanted with chrome, use:

1 to 1% pecks fresh coreopsis flower heads.

Mordant the wool with chrome (p. 6). Boil the flowers in water to cover

for 10 or 15 minutes, strain, and add enough cold water to make 4 to 4%

gallons for the dye bath. Immerse the yarn or cloth, thoroughly rinsed and

squeezed out of water, and boil for 20 minutes or until the desired color

is obtained. Rinse and dry.

COTTON FLOWERS (GoSSypium Sp.)

The flowers of the cotton plant, one of our main sources of textile

fibers, also furnish a dye. Cotton flowers may be used fresh for dyeing,

or dry and finely crushed.

On wool mordanted with chrome, cotton flowers give a brass color that

has fair fastness to light and good fastness to washing. By another

method, they produce a yellow-tan with good color fastness. On cotton,

these flowers give a yellow and a yellow-tan, which have fair and good

color fastness respectively.

Brass.—For each pound of wool mordanted with chrome, allow: 1%

quarts dry cotton flowers.

Mordant the wool with chrome (p.

6). Boil the dry crushed cotton flowers for 20 minutes, strain, and add

enough cold water to make 4 to 4% gallons for the dye bath. Immerse

the yarn or cloth thoroughly rinsed and squeezed out of water, and boil

for 30 minutes. Rinse and dry.

Yellow-tan.—For each pound of

wool mordanted with alum, or for each pound of cotton mordanted with

alum-tannin-alum, allow:

1% quarts dry crushed cotton

flowers.

% ounce potassium dichromate.

% ounce acetic acid, or 6 to 7

tablespoons vinegar.

Mordant the wool with alum (p. 6) or the cotton with alum-tannin-alum

(p. 6), and dye as directed under Brass. Then without rinsing put the

material into a boiling bath of the potassium dichromate and acetic acid

in 4 to 4% gallons of water, and boil for 10 minutes longer. Rinse and

dry.

Yellow.—For each pound of cotton mordanted with alum-tannin-alum,

allow:

1% quarts dry cotton flowers.

Mordant the cotton with alum-tannin-alum (p. 6) and dye as directed for

Brass.

10626°—3E

|

|

| |

18 |

18 MISC. PUBLICATION 230, U. S. DEPT. OF AGRICULTURE

cutch (Acacia sp.)

Cutch or catechu, one of the most important brown vegetable dyes, is

the dried extract obtained from the wood of various species of acacia

growing in India, Java, and the East Indies. Cutch can be obtained from

houses supplying dyes and botanical drugs.

On both wool and cotton, cutch gives a fine rich brown when applied

with copper sulphate and potassium dichrpmate. On cotton, its fastness to

light is fair, and fastness to washing good; on wool, both are good.

Brown.—For each pound of dry wool or cotton, allow:

4 ounces cutch.

Yz ounce copper sulphate.

% ounce potassium dichromate.

Boil the cutch and copper sulphate in water until well dissolved. While

still hot, put in the yarn or cloth which has been boiling a short time in

clear water, stir well, and let stand overnight. In the morning squeeze

the material from the cutch solution and put into a hot bath made by

dissolving the potassium dichromate in 4 to 4V2

gallons of soft water. Stir well and let stand in this for 45 minutes just

below boiling temperature. Rinse and dry.

dahlia flowers (Dahlia sp.)

The dahlias common in flower

gardens furnish a good source of orange dye for wool. Yellow flowers give

clearer and brighter colors than pink ones although their color fastness

is the same. On wool mordanted with chrome, yellow dahlia flowers give an

orange color that has fair fastness to light and good fastness to washing.

The yellow obtained with an alum mordant has poor fastness to light.

Dahlia flowers do not dye cotton.

Orange.—For each pound of wool

mordanted with chrome, use: 1 to 1% pecks fresh dahlia flowers.

Mordant the wool with chrome (p.

6). Cut the flowers up and boil in water to cover for 10 to 15 minutes,

strain, and add enough cold water to make 4 to 4% gallons for the dye

bath. Immerse the yarn or cloth thoroughly rinsed and squeezed out of

water, and boil for 20 minutes. Rinse and dry.

fustic (Chlorophora tinctoria)

Fustic is probably one of the best yellow dyes found in nature. It is

obtained from the wood of a tree that grows in Mexico, Cuba, and

Nicaragua. It can be purchased either as wood chips or as an extract.

On wool, fustic produces a gold color and a dark yellow-tan. On cotton,

it gives a lighter yellow-tan. All have good color fastness. The colors

with alum and tin mordants are brighter but their fastness is poor.

Gold.—For each pound of wool mordanted with chrome, use:

yi ounce fustic extract.

Mordant the wool with chrome (p. 6). Dissolve the fustic in enough

water for the dye bath (4 to 4% gallons), immerse the yarn or

cloth, thoroughly rinsed and squeezed out of water, and boil for 30

|

|

| |

19 |

HOME DYEING WITH NATURAL DYES 19

minutes. Rinse and dry. Prolonged boiling should be avoided as this causes

the color to become dull and brown.

Yellow-tan.—For each pound of wool mordanted with alum, or for each

pound of cotton mordanted with alum-tannin-alum, allow:

% ounce fustic extract.

Ye ounce potassium dichromate.

% ounce acetic acid, or 6 to 7 tablespoons of vinegar.

Mordant the wool with alum (p. 6) and the cotton with alum-tannin-alum

(p. 6), and dye as directed for Gold. Without rinsing put the material

into a boiling bath of the potassium dichromate and acetic acid in 4 to

4l/2 gallons of water and boil 10

minutes longer. Rinse and dry. On cotton the color is much lighter than on

wool.

GOLDENEOD FLOWERS (SolidagO Sp.)

Flowers of the goldenrod that grow wild in fields and along roadsides

can be used for dyeing wool. They give a brass color and a yellow-brown.

With indigo, goldenrod gives dark-green shades; with madder, a terra cotta

and a rose-brown. All of these colors have good fastness to light and to

washing. The greenish yellow that goldenrod gives on wool mordanted with

alum and the colors it produces on cotton are not fast to light.

The goldenrod flowers should be picked as they are coming into bloom

and used fresh.

Brass.—For each pound of wool mordanted with chrome, use: '

1 to \Yz pecks fresh goldenrod flowers.

Mordant the wool with chrome (p. 6). Boil the flowers in water to cover

for 10 to 15 minutes, strain, and add enough cold water to make 4 to 4K

gallons for the dye bath. Immerse the yarn or cloth thoroughly wet and

squeezed out of water and boil for 20 minutes. Rinse and dry.

Yellow-brown.—For each pound of wool mordanted with alum, allow:

1 to 1% pecks fresh goldenrod flowers.

% ounce potassium dichromate.

% ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p. 6), and dye as directed for Brass. Then

without rinsing put the yarn or cloth into a boiling-bath of the potassium

dichromate and acetic acid in 4 to 4% gallons of water. Stir carefully and

boil for 10 minutes. Rinse and dry.

hickory nut hulls (Hicoria laciniosa)

This hickory tree, commonly called big shellbark, grows throughout the

eastern half of the United States from New York to Iowa and south to

Tennessee and Oklahoma. The hulls are very large and thick and produce a

light brown on wool. The color fastness is good.

Light brown.—For each pound of wool mordanted with alum, allow:

1 peck green hickory nut hulls. % ounce potassium dichromate.

Y& ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p.

6). Cut up the green hulls and soak overnight in water to cover. In the

morning heat gradually, let |

|

| |

20 |

20 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICULTURE boil 45

minutes, strain, and add water to make 4 to 4% gallons for the dye

bath. Immerse the wool material thoroughly rinsed and squeezed out of

water and boil 30 minutes. Without rinsing put in a boiling bath of the

potassium dichromate and acetic acid, stir carefully, and boil for 10

minutes. Rinse and dry.

hollygrape boot (Berberis sp.)

The coloring matter contained in Ijollygrape root is berberine, the

same as that present in the bark and root of barberry. It is one of the

few natural basic dyestuffs. Hollygrape, or Oregon grape as it is

sometimes called, grows in the Northwestern States. On wool, hollygrape

root gives a buff and a light tan which have fair color fastness. On

cotton its colors are not fast.

Buff.—For each pound of wool mordanted with alum, allow: 1 peck chopped

hollygrape root.

Mordant the wool with alum (p. 6). Soak the chopped root overnight in

water to cover. In the morning boil for 2 hours, strain, and add enough

water to make 4 to 4% gallons for the dye bath. Immerse the yarn or cloth

thoroughly rinsed and squeezed out of water 'and boil for 30 minutes.

Rinse and dry.

Tan.—For each pound of wool mordanted with alum, allow:

1 peck chopped hollygrape root. l/& ounce potassium

dichromate. % ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p. 6) and dye as directed above. Without

rinsing put into a boiling bath of the potassium dichromate and acetic

acid, stir carefully, and boil 10 minutes longer. Rinse and dry.

indigo (Indigofera sp.)

Indigo, one of the oldest dyestuffs known, was probably first used in

India and Egypt. During the sixteenth century it was introduced into

Europe where it met with much opposition from the cultivators of a similar

dye—woad. Indigo is still extensively used and can be obtained at many

dye-supply houses. On both wool and cotton it produces a dark blue that is

very fast to light and to washing.

Indigo does not require a mordant. It belongs to the group of vat dyes,

so called because they are applied in a special kind of dye bath called a

vat. Since indigo itself is not soluble in water, it must first be changed

by a reducing agent and then dissolved in alkali so that the wool or

cotton fiber can take it up. The material is dyed by repeatedly dipping it

in the dye vat and holding it in the air until the desired color is

developed and permanently fixed in the fiber. The fermentation and

hydrosulphite vats are described here.

INDIGO FERMENTATION VAT OR BLUE-POT

The fermentation vat or blue-pot is the oldest method of dyeing with

indigo. The bacteria that develop in the vat act on the dye to reduce and

change it. Although dyeing by this method is somewhat complicated, there

is no difficulty in developing a good, fast dark blue on both wool and

cotton if the vat is properly prepared. With fewer dips, a medium blue and

a light blue are obtained.

|

|

| |

21 |

HOME DYEING WITH NATURAL DYES 21

Dark blue.—For each pound of wool or cotton, allow:

8 ounces finely powdered indigo.

4 ounces wheat bran.

4 ounces madder.

\% pounds sodium carbonate (washing soda).

4 gallons water.

Mix ingredients and let stand in a warm place (85° F.) from 5 to 10

days until the mixture develops a disagreeable odor, a bluish, coppery

scum on top, and green streaks through it. The dye is then ready to use.

The blue-pot should be stirred well, each morning.

Wool yarn or cloth may be dyed in the indigo vat without a mordant,

though some dyers prefer mordanting with alum (p. 6). Good results are

also obtained when the wool, before being dyed, is soaked for 30 minutes

in a solution of one-half ounce of washing soda to 4 gallons of lukewarm

water and rinsed well. If the indigo-dyed wool is to be top-dyed with

yellow it is advisable to mordant with alum either before or after dying

with indigo.

Cotton yarn or cloth is also dyed without a mordant, though sometimes

it is mordanted with alum (p. 6). Another method of preparing cotton for

dyeing is to boil it for 30 minutes in a solution of one-half ounce of

sodium hydroxide to 4 gallons of water, and rinse well.

To dye with the indigo vat, first wet the wool or cotton thoroughly,

then dip it in the vat, which should be kept lukewarm, stir well, and lift

the fabric out into the air at intervals. The cloth will be greenish

yellow in the dye vat but on being taken out in the air, will soon develop

the blue color. Continue the dipping and airing for 30 minutes, then

squeeze out the dye, and air for half an hour. Repeat this process several

times, increasing the time of immersion of the cloth in the dye until the

desired color is obtained. Also turn and stir the material in the dye

occasionally to insure an even color. When the color is dark enough, rinse

the material in lukewarm water and dry. Fewer dippings will give a medium

blue and a light blue.

Take care not to disturb the sediment in the vat, or the fabrics will

be streaked and unevenly dyed. Also do not stir the dye vat too much, or

it will turn blue and no longer be fit for dyeing. In case it does become

blue, the vat can be renewed by adding more indigo, bran, madder, and

sodium carbonate. After standing for a day or two, it will be ready to use

again. In this way the blue-pot is kept going and can be used many times.

INDIGO HYDROSULPHITE VAT

The hydrosulphite vat is the most easily regulated of the indigo vats

and is extensively used at present. A stock solution of indigo, an alkali,

and hydrosulphite is prepared as follows and the dye vat is made up by

adding this solution to water:

4% ounces powdered indigo. 3 ounces sodium hydroxide. 2%

ounces sodium hydrosulphite.

Mix the powdered indigo with the

sodium hydroxide which has been dissolved in water. Add water to make 1

gallon and heat to 120° F. Stir well and add the sodium hydrosulphite

slowly. Let stand for 30 minutes. The liquid should be clear and yellow,

and a |

|

| |

22 |

22 MISC. PUBLICATION 230, U. S. DEPT. OF

AGRICULTURE drop

running on a sheet of glass should require about 25 seconds to turn blue.

Extra stock solution may be kept in a stoppered bottle. Dark blue.—For

each pound of wool or cotton, allow:

2 to 2K quarts indigo hydrosulphite stock solution.

% to % cup sodium hydrosulphite solution (prepared by slowly

adding %

ounce sodium hydrosulphite to 1 quart water and keeping the solution

in a stoppered bottle).

Heat the water for the dye vat to 120° F., add the half cup of sodium

hydrosulphite solution, stir well, and let stand for 10 minutes. Then add

the indigo hydrosulphite stock solution, stir gently, and allow to stand

for 20 minutes. The vat is then ready to use for dyeing. The liquor should

be clear and yellow in color.

Both wool and cotton are dyed in the hydrosulphite vat without

mordants. In case the material is to be top-dyed with another color, it is

advisable to mordant with alum (p. 6) either before or after dyeing with

indigo. However, this depends on the dye that is to follow.

To dye with this vat, first wet the cloth well, then dip it in the vat,

and stir occasionally for 30 minutes, always keeping the material well

covered with the dye. Without squeezing or rinsing, hang it in the air for

30 minutes, then dip again in the vat. Continue this dipping and airing

until the desired color is obtained, then rinse thoroughly, wash in

soapsuds, and rinse again. If the vat turns blue, add more sodium

hydrosulphite solution, stir the vat carefully, and let stand for 15

minutes before using. Also add more of the indigo hydrosulphite stock

solution as needed.

IRON BUFF

On cotton without a mordant, ferrous sulphate produces a buff color

that has fair fastness to light and washing. On wool the fastness to light

is poor.

Buff.—For each pound of dry unmordanted cotton yarn or cloth, use:

6 ounces ferrous sulphate (copperas). 6 ounces powdered soap.

Dissolve the ferrous sulphate in 4 to 4K gallons of water, put in the

cotton, thoroughly wet and squeezed out of water, stir for a few minutes,

remove, and drain. Then dip it into soapsuds, stir, and wring. Repeat

three times; then rinse and dry.

juniper berries (Juniperus sp.)

Juniper, also called red cedar, grows in many sections of the United

States. The bark, berries, and twigs are suitable for dyeing purposes. On

wool, juniper berries give a khaki color when applied with alum and copper

sulphate. It is fast to light and to washing. Juniper berries do not dye

cotton.

Khaki.—For each pound of wool, allow:

2 quarts ripe juniper berries. 2 ounces potash alum. % ounce

ammonium chloride. 1 ounce cream of tartar. 1 ounce copper sulphate. 1

ounce copper acetate.

|

|

| |

23 |

HOME DYEING WITH NATURAL DYES 23

Dissolve the alum, ammonium chloride, cream of tartar, and copper sulphate

in 4 to 4% gallons of soft water. Put in the wool, wet thoroughly and

squeezed out of water, boil for 1 hour, and let stand in this mordanting

liquor until cold, then rinse. Break up the berries, tie in a cheesecloth

bag, soak in water overnight, then boil for 1 hour and add enough cold

water for the dye bath. Immerse the mordanted wool in this dye extract,

boil for 1 to 2 hours, and remove. Add the copper acetate to the dye bath

and when dissolved, return the yarn or cloth, and boil for 15 to 30

minutes longer. Rinse and dry.

LICHENS

The peasant dyers of Sweden, Scotland, and Ireland use lichens for

coloring woolens various shades of brown, yellow, red, and purple. August

is probably the best month to collect dye lichens, when they contain the

most acid and the colors are stronger and clearer. It is said that lichens

growing on stones give a better color than the same lichens growing on

trees.

lichen i (Peltigera sp.)

Lichens of the genus Peltigera are flat and leaf like. They grow

on rocks and on trees and are very abundant in all parts of North America,

especially in the mountains of the South.

The lichens used for these tests on wool gave a yellow-tan and a dark

rose-tan. Both have fair fastness to light and good fastness to washing.

Yellow-tan.—For each pound of wool mordanted with alum, allow: 1

peck crushed dry lichens.

Mordant the wool with alum (p. 6). Soak the lichens overnight in water

to cover; in the morning heat gradually and boil for 1 hour. Strain and

add cold water to make 4 to 4% gallons for the dye bath. Immerse

the wool thoroughly rinsed and squeezed out of water, and boil for 30

minutes. Rinse and dry.

Dark rose-tan.—For each pound of wool mordanted with alum, allow:

1 peck crushed dry lichens.

% ounce potassium dichromate.

% ounce acetic acid, or 6 to 7 tablespoons vinegar.

Mordant the wool with alum (p. 6) and dye as directed under Yellow-Tan.